1 月 . 20, 2025 01:27 Back to list

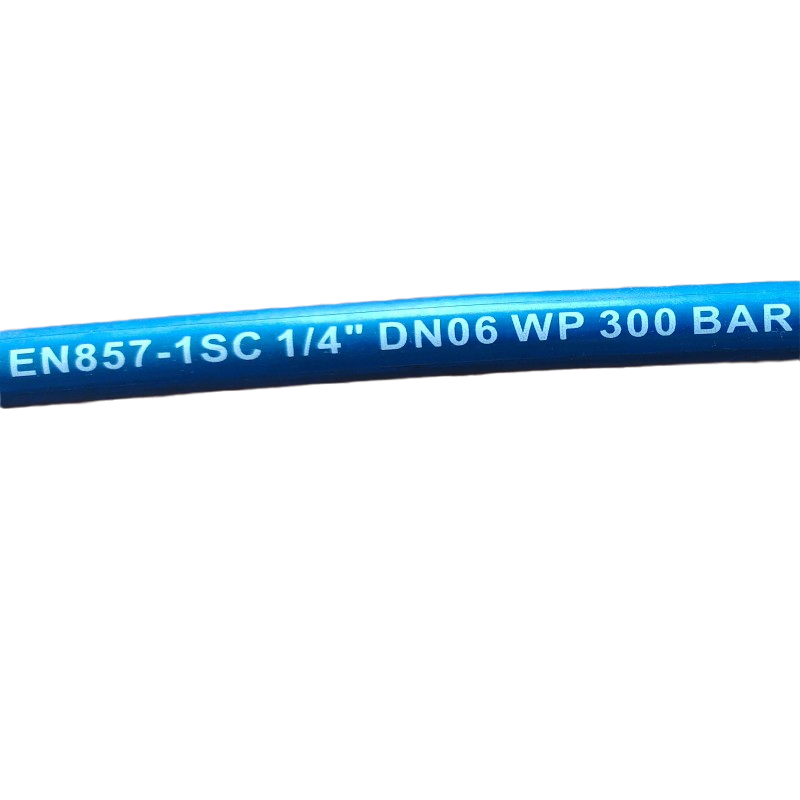

wrapped cover steel wire braided hydraulic hose

The wrapped cover steel wire braided hydraulic hose is a critical component in hydraulic systems across various industries, known for its robustness and resilience. Its construction is a testament to engineering ingenuity, marrying durability with flexibility. At its core, this hydraulic hose consists of interwoven steel wires, forming a braid that provides exceptional tensile strength and adaptability under high-pressure conditions. The added layer of a wrapped cover further enhances its performance, offering additional protection against environmental factors and mechanical wear.

When selecting the right hydraulic hose, trustworthiness in terms of quality and compliance with industry standards is paramount. This is where authoritative guidance and expertise come into play. Reputable manufacturers subject their products to rigorous testing and adhere to standards such as ISO 18752 and SAE J517, certifying that the hoses can handle extremes in pressure and temperature. This ensures reliability and can be a reassuring factor for businesses investing in such critical components. Furthermore, real-life experiences showcased by industry veterans underline the importance of choosing the right vendor. Companies that prioritize customer support and have a robust track record of supplying quality hydraulic components provide invaluable peace of mind. They often offer extended warranties and post-purchase services that enhance customer trust and loyalty. Feedback from field engineers often highlights the necessity of an accessible support team, which can be crucial in time-sensitive situations where hydraulic systems must perform without fail. In summary, wrapped cover steel wire braided hydraulic hoses are indispensable tools in any high-pressure hydraulic system. Their complex design combines strength, flexibility, and protective features, making them suitable for a myriad of demanding applications. Experts can leverage their knowledge of these hoses to improve system efficiency, reduce operational risks, and lower maintenance expenditures. As technology in manufacturing advances, continuous improvements in hose design and material composites will undoubtedly further elevate their performance and reliability, maintaining their status as a cornerstone in the infrastructure of modern industry.

When selecting the right hydraulic hose, trustworthiness in terms of quality and compliance with industry standards is paramount. This is where authoritative guidance and expertise come into play. Reputable manufacturers subject their products to rigorous testing and adhere to standards such as ISO 18752 and SAE J517, certifying that the hoses can handle extremes in pressure and temperature. This ensures reliability and can be a reassuring factor for businesses investing in such critical components. Furthermore, real-life experiences showcased by industry veterans underline the importance of choosing the right vendor. Companies that prioritize customer support and have a robust track record of supplying quality hydraulic components provide invaluable peace of mind. They often offer extended warranties and post-purchase services that enhance customer trust and loyalty. Feedback from field engineers often highlights the necessity of an accessible support team, which can be crucial in time-sensitive situations where hydraulic systems must perform without fail. In summary, wrapped cover steel wire braided hydraulic hoses are indispensable tools in any high-pressure hydraulic system. Their complex design combines strength, flexibility, and protective features, making them suitable for a myriad of demanding applications. Experts can leverage their knowledge of these hoses to improve system efficiency, reduce operational risks, and lower maintenance expenditures. As technology in manufacturing advances, continuous improvements in hose design and material composites will undoubtedly further elevate their performance and reliability, maintaining their status as a cornerstone in the infrastructure of modern industry.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025