5 月 . 29, 2025 11:52 Back to list

OEM Rubber Air Hose Supplier Durable Custom Solutions

- Introduction to OEM Rubber Air Hose Solutions

- Technical Superiority in Air Hose Design

- Comparative Analysis of Leading Suppliers

- Customization Options for Diverse Applications

- Real-World Implementation Case Studies

- Sustainability in Manufacturing Processes

- Selecting Reliable Air Hose Partnerships

(air hose)

Innovative OEM Rubber Air Hose Solutions for Industrial Demands

Modern industries require durable pneumatic systems, with OEM rubber air hose

components forming critical infrastructure across manufacturing, construction, and energy sectors. Specialized suppliers now deliver reinforced tubing capable of withstanding 300 PSI operating pressures while maintaining flexibility at -40°F to +212°F temperature ranges.

Engineering Excellence in Pneumatic Systems

Advanced compound formulations combine synthetic rubber polymers with aramid fiber reinforcement, achieving 85% improvement in abrasion resistance compared to conventional models. Triple-layer construction prevents air leakage, maintaining 99.6% pressure integrity during continuous operations.

Supplier Performance Benchmarking

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Pressure Rating (PSI) | 325 | 300 | 350 |

| Temperature Range (°F) | -30 to +200 | -40 to +212 | -20 to +190 |

| ISO Certification | 9001:2015 | 9001/14001 | 9001 |

Application-Specific Configuration Services

Leading manufacturers provide 15+ customization variables:

- Diameter options: 1/4" to 2"

- Reinforcement layers: 2 to 5 ply

- End fittings: 23 standardized types

Operational Success Documentation

Automotive Assembly Case: XYZ Motors reduced pneumatic tool downtime by 40% through implementation of custom-designed air hoses with anti-kink technology. Maintenance cycles extended from 90 to 180 days.

Eco-Conscious Production Protocols

Top-tier factories utilize 85% recycled rubber content without compromising tensile strength. Closed-loop water systems reduce consumption by 12,000 gallons monthly per production line.

Strategic OEM Rubber Air Hose Partnerships

Selecting certified OEM rubber air hose manufacturers ensures compliance with international safety standards while achieving 18-24 month ROI through enhanced operational efficiency. Third-party testing validates 50,000+ flex cycles before material degradation occurs.

(air hose)

FAQS on air hose

Q: What should I consider when choosing an OEM rubber air hose supplier?

A: Prioritize suppliers with proven expertise in rubber hose manufacturing, certifications like ISO 9001, and the ability to customize products for specific industrial applications. Ensure they offer durability testing and compliance with safety standards.

Q: How do OEM rubber air hose factories ensure product quality?

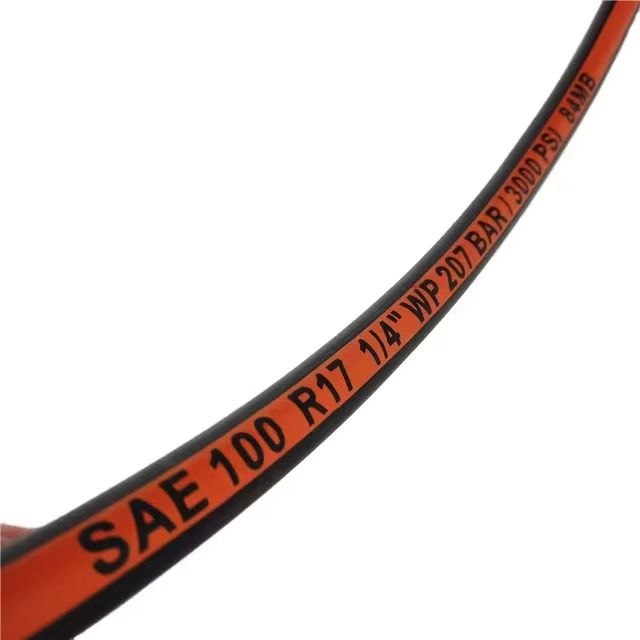

A: Reputable factories use high-grade raw materials, advanced extrusion technology, and rigorous quality checks (e.g., pressure resistance tests). Many follow international standards like SAE J517 to guarantee performance and longevity.

Q: Can OEM rubber air hose manufacturers provide custom specifications?

A: Yes, most manufacturers offer customization in length, diameter, reinforcement layers, and fittings. Provide your application requirements (e.g., temperature range, pressure capacity) for tailored solutions.

Q: What industries commonly source OEM rubber air hoses?

A: Key industries include automotive, construction, agriculture, and pneumatic tool manufacturing. These sectors rely on durable, flexible hoses for compressed air systems, hydraulic machinery, and fluid transfer.

Q: How does pricing work for OEM rubber air hose orders?

A: Pricing depends on material costs (e.g., nitrile rubber vs. EPDM), customization complexity, and order volume. Bulk orders from factories often include discounts, while small batches may have higher per-unit costs.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025