1 月 . 17, 2025 05:42 Back to list

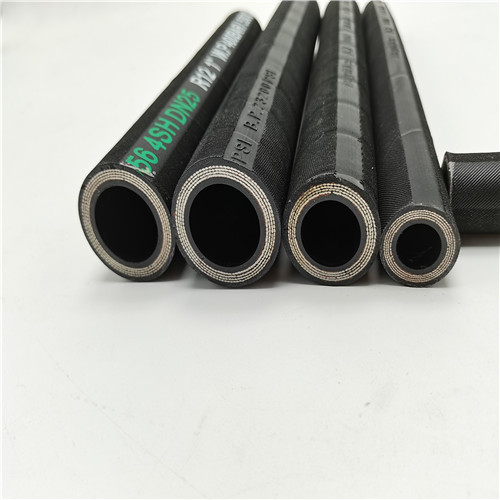

SAE100R1AT/ DIN EN853 1SN Black Smooth Cover Hydraulic Hose

Wire spiral high pressure hydraulic hoses are quintessential components in today's industrial landscape, known for their ability to withstand extreme pressure and demanding conditions. Primarily used in heavy machinery, construction equipment, and various hydraulic systems, these hoses play a critical role in ensuring efficient fluid conveyance without leakage or breakage. With a range of applications, choosing the right wire spiral hydraulic hose can make a significant difference in operational effectiveness.

Authoritative sources in the hydraulic industry often discuss the evolution of hose technology, highlighting innovations such as improved materials and reinforcement techniques. For instance, modern hoses incorporate thermoplastic elastomers or synthetic rubber compounds that enhance flexibility and temperature resistance. Moreover, continuous advancements in spiral winding processes have led to hoses that can endure more significant pressure pulses without compromising structural integrity. Trustworthiness in choosing wire spiral high-pressure hydraulic hoses is further cemented by selecting providers with an established reputation for quality and reliability. Manufacturers that offer extensive warranties, comprehensive product testing, and stellar customer support are often preferred due to their commitment to customer satisfaction and safety assurance. Product specialists also stress the importance of proper hose installation and end fittings. The right coupling and secure attachment ensure the hose performs to its fullest potential and minimizes the risk of disconnections under pressure. As such, employing qualified technicians for hose assembly and installation is advisable to guarantee a balanced and efficient hydraulic system. Furthermore, understanding the environmental conditions in which these hoses operate can markedly impact their performance. For operations in extreme temperatures or exposure to harsh chemicals, selecting hoses with additional protective coverings or resistant outer layers optimizes longevity and reduces replacement frequency. In conclusion, wire spiral high-pressure hydraulic hoses are integral to achieving seamless and safe industrial operations. Their design, enhanced by technological advancements and expert insights, allows them to meet the rigorous demands of modern hydraulic systems efficiently. By understanding their construction, maintenance needs, and applications, businesses can benefit from their reliability and robust performance, safeguarding both machinery and workforce.

Authoritative sources in the hydraulic industry often discuss the evolution of hose technology, highlighting innovations such as improved materials and reinforcement techniques. For instance, modern hoses incorporate thermoplastic elastomers or synthetic rubber compounds that enhance flexibility and temperature resistance. Moreover, continuous advancements in spiral winding processes have led to hoses that can endure more significant pressure pulses without compromising structural integrity. Trustworthiness in choosing wire spiral high-pressure hydraulic hoses is further cemented by selecting providers with an established reputation for quality and reliability. Manufacturers that offer extensive warranties, comprehensive product testing, and stellar customer support are often preferred due to their commitment to customer satisfaction and safety assurance. Product specialists also stress the importance of proper hose installation and end fittings. The right coupling and secure attachment ensure the hose performs to its fullest potential and minimizes the risk of disconnections under pressure. As such, employing qualified technicians for hose assembly and installation is advisable to guarantee a balanced and efficient hydraulic system. Furthermore, understanding the environmental conditions in which these hoses operate can markedly impact their performance. For operations in extreme temperatures or exposure to harsh chemicals, selecting hoses with additional protective coverings or resistant outer layers optimizes longevity and reduces replacement frequency. In conclusion, wire spiral high-pressure hydraulic hoses are integral to achieving seamless and safe industrial operations. Their design, enhanced by technological advancements and expert insights, allows them to meet the rigorous demands of modern hydraulic systems efficiently. By understanding their construction, maintenance needs, and applications, businesses can benefit from their reliability and robust performance, safeguarding both machinery and workforce.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025