8 月 . 16, 2024 09:06 Back to list

Top Suppliers for High Pressure Hydraulic Hose Fittings in the Industry Today

High Pressure Hydraulic Hose Fittings Suppliers

In the world of hydraulic systems, the integrity and efficiency of a hydraulic hose are paramount. High-pressure hydraulic hose fittings play a crucial role in ensuring that these systems operate smoothly, safely, and reliably. Suppliers who specialize in high-pressure hydraulic hose fittings provide essential components that connect hoses to various hydraulic applications in industries such as construction, manufacturing, and automotive.

Understanding High-Pressure Hydraulic Hose Fittings

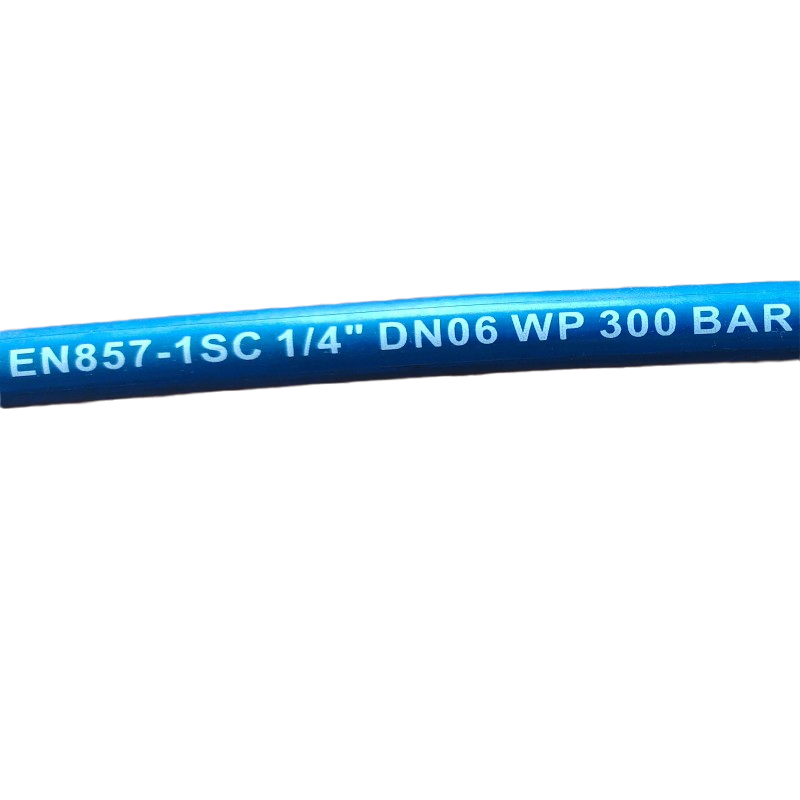

High-pressure hydraulic hose fittings are specialized components designed to withstand the demanding conditions of hydraulic systems. These fittings are used to connect hydraulic hoses to pumps, cylinders, and other equipment while maintaining the structural integrity necessary to handle high-pressure fluids. The design of these fittings involves rigorous engineering to ensure that they can tolerate extreme temperatures, high pressures, and aggressive fluids without failing.

The Importance of Quality Suppliers

Choosing the right supplier for high-pressure hydraulic hose fittings is vital. Quality suppliers ensure that their products meet strict industry standards and regulations, such as those set by the American National Standards Institute (ANSI) and the Society of Automotive Engineers (SAE). A reliable supplier will provide certifications and testing results that attest to the strength and safety of their fittings. This not only helps in preventing equipment failures but also enhances the overall safety of hydraulic systems.

Key Considerations When Selecting a Supplier

When looking for high-pressure hydraulic hose fittings suppliers, several factors should be taken into account

1. Product Range A good supplier should offer a wide variety of fittings, including different sizes, materials, and configurations. This variety ensures that you can find the right components for your specific application.

high pressure hydraulic hose fittings suppliers

2. Quality Assurance Look for suppliers who implement rigorous quality control measures. This can include specific testing protocols, certifications, and adherence to industry standards.

3. Technical Support A knowledgeable supplier will provide technical assistance to help customers choose the right fittings for their applications. Additionally, they can offer guidance on installation and maintenance practices.

4. Responsive Customer Service Efficient and responsive customer service is essential, especially when dealing with high-pressure systems where downtime can be costly. A good supplier should be accessible and able to address inquiries or issues promptly.

5. Competitive Pricing While price should not be the sole consideration, it is important to find suppliers that provide high-quality products at competitive rates. Comparing prices without compromising on quality will help you find the best value.

Trends in the Hydraulic Fittings Market

The hydraulic fittings market is continually evolving. With advancements in technology and materials, manufacturers are now producing fittings that are lighter, stronger, and more resistant to corrosion and fatigue. The shift towards telematics and automation in various industries is also influencing the demand for more sophisticated hydraulic systems, further driving the need for high-quality components.

Moreover, as industries become more environmentally conscious, suppliers are focusing on products that reduce leakage and improve system efficiency, contributing to sustainability goals.

Conclusion

High-pressure hydraulic hose fittings are integral to the performance and safety of hydraulic systems. Selecting a quality supplier is essential for ensuring the reliability of these components. By focusing on product range, quality assurance, technical support, customer service, and competitive pricing, industries can navigate the complexities of high-pressure hydraulic systems with confidence. As technology continues to advance, staying informed about industry trends will further enhance operational efficiency and safety in hydraulic applications.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025