8 月 . 17, 2024 23:48 Back to list

Top OEM Manufacturers for 3/4 Inch Air Hose Solutions and Customizations Available Today

The Role of OEM 3/4 Air Hose Manufacturers in Today's Industry

In an era where efficiency and precision are paramount, OEM (Original Equipment Manufacturer) 3/4 air hose manufacturers hold a significant position in the industrial supply chain. Air hoses are indispensable components in various applications, from automotive repairs to construction and manufacturing. Understanding the importance of these manufacturers helps us appreciate the intricate role they play in facilitating smooth operations and maintaining high standards in various industries.

What is an OEM Air Hose?

An OEM air hose is specifically designed to meet the unique requirements of original equipment manufacturers. Unlike generic hoses, OEM hoses are tailored to fit specific machines or equipment, ensuring optimal performance. The 3/4 inch designation refers to the diameter of the hose, which is commonly used for pneumatic tools and other equipment that require reliable air supply.

The Importance of Quality

Quality is a critical factor when it comes to air hoses. OEM manufacturers invest significant resources in research and development to create hoses that can withstand high pressure, extreme temperatures, and various environmental conditions. They use advanced materials such as rubber, PVC, and polyurethane, which offer durability and flexibility. A high-quality air hose can prevent leaks, reduce downtime, and enhance overall productivity in the workplace.

Customization and Design

One of the key advantages of working with OEM manufacturers is the ability to customize designs according to specific needs. Businesses often require hoses that fit within tight spatial constraints or that conform to unique operational requirements. OEM 3/4 air hose manufacturers are equipped to create solutions that are not only functional but also adhere to industry standards and regulations. This level of customization helps companies improve efficiency and reduce the risk of equipment malfunctions.

oem 3/4 air hose manufacturers

Economic Benefits

Partnering with OEM manufacturers can lead to significant economic advantages. Tailor-made products often reduce maintenance and replacement costs over time. Moreover, by ensuring that the equipment operates at maximum efficiency, businesses can save on energy costs. The initial investment in quality OEM hoses can translate into long-term savings, as fewer replacements and repairs are needed.

Environmental Considerations

As global awareness of environmental issues grows, OEM air hose manufacturers are increasingly focused on sustainability. Many manufacturers are adopting eco-friendly materials and production methods to minimize their carbon footprint. This not only benefits the environment but also aligns with the corporate social responsibility goals of businesses that are committed to sustainable practices.

Market Trends and Innovations

The market for air hoses continues to evolve, with manufacturers constantly innovating to keep pace with technological advancements. Features such as lightweight designs, improved kink resistance, and anti-static properties are becoming standard expectations among consumers. Additionally, the rise of smart technologies in the manufacturing sector has introduced opportunities for integrating sensors and monitoring systems into air hoses, providing real-time data on performance and safety.

Conclusion

OEM 3/4 air hose manufacturers are vital players in the industrial landscape, ensuring that businesses have access to high-quality, reliable hoses tailored to their unique needs. By focusing on quality, customization, and sustainability, these manufacturers contribute to enhanced operational efficiency, economic savings, and environmental stewardship. As industries continue to evolve, the role of OEM manufacturers will remain crucial in shaping the future of air supply solutions. Companies that prioritize working with these manufacturers will likely benefit from improved performance and competitiveness in the marketplace.

-

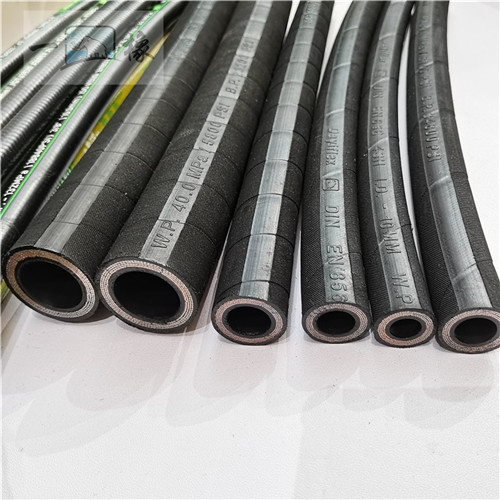

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025