8 月 . 16, 2024 09:03 Back to list

Top Manufacturers of Customizable Flexible Air Hoses for OEM Applications and Industrial Use

Understanding OEM Flexible Air Hose Factories

In the industrial realm, the demand for efficient, durable, and flexible air hoses has surged due to the rising applications in various sectors, including manufacturing, construction, and automotive. Original Equipment Manufacturer (OEM) flexible air hose factories play a critical role in producing these essential components, catering to the specific needs of different industries. This article sheds light on the significance, manufacturing process, and benefits of using OEM flexible air hoses.

What is an OEM Flexible Air Hose?

An OEM flexible air hose is specifically designed to meet the requirements of specific machinery or equipment, ensuring compatibility and functionality. These hoses are manufactured according to precise specifications provided by clients or end-users, making them tailored solutions for various applications. Unlike generic hoses, OEM products are crafted to fit seamlessly into existing systems, enhancing performance and reliability.

The Manufacturing Process

The production of OEM flexible air hoses involves several stages, starting from material selection. The hoses are typically made from materials like rubber, PVC, polyurethane, or other synthetic compounds, chosen for their flexibility, durability, and resistance to abrasion and temperature fluctuations.

1. Material Selection High-quality polymers are selected based on the intended use, such as high-pressure applications, corrosive environments, or temperature extremes.

2. Extrusion The selected materials undergo an extrusion process, where they are heated and formed into the desired hose shape. This method ensures uniform wall thickness and flexibility.

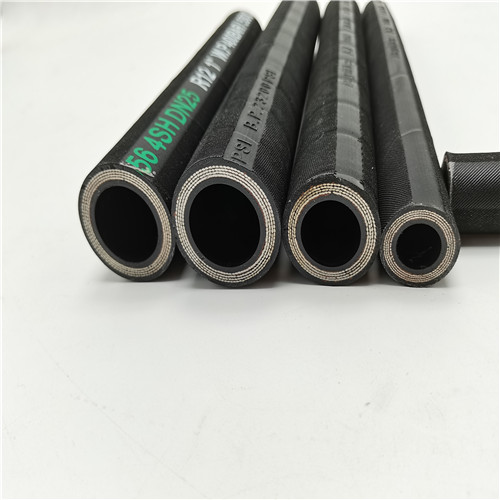

3. Reinforcement Many air hoses require reinforcement to withstand high pressures. Materials such as textile braiding or steel wire may be incorporated to provide additional strength and durability.

4. Cutting and Assembly After extrusion, the hoses are cut to specified lengths, and fittings or connectors are added as needed. This assembly allows the hoses to be used immediately in various applications.

oem flexible air hose factories

5. Testing Quality control is paramount in the production process. Each batch of hoses undergoes rigorous testing to ensure they meet the industry standards for pressure resistance, flexibility, and durability.

6. Packaging and Distribution Finally, the finished products are meticulously packaged and distributed to clients or retailers, ready for installation in various systems.

Benefits of Using OEM Flexible Air Hoses

1. Customization One of the primary advantages of OEM flexible air hoses is their customization. Manufacturers can design hoses tailored to specific applications, including size, length, and material properties, enabling better integration with existing systems.

2. High Quality and Reliability OEM factories often adhere to strict quality control standards and utilize premium materials, resulting in hoses that are reliable and durable over time. This reliability translates to less downtime and reduced maintenance costs for businesses.

3. Performance Enhancement Custom-designed air hoses enhance system performance by ensuring optimal airflow and pressure management. This efficiency can lead to increased productivity and improved operational outcomes.

4. Cost-effectiveness While OEM hoses may have a higher upfront cost, their durability and performance can lead to long-term savings. Reduced replacement rates and lower maintenance costs contribute to overall cost-effectiveness.

5. Industry Standards Compliance OEM flexible air hoses are often designed to comply with industry standards, ensuring that they meet safety regulations and performance criteria essential for various applications.

Conclusion

OEM flexible air hose factories play an indispensable role in meeting the unique demands of various industries. With their focus on customization, quality, and performance, these manufacturers provide components that enhance operational efficiency and reliability. As industries continue to evolve, the significance of tailored solutions, like OEM flexible air hoses, will only grow, ensuring that equipment operates at optimal levels while meeting the challenges of modern applications.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025