8 月 . 21, 2024 00:38 Back to list

Teflon Flexible Hose Manufacturing Process and Industry Insights for Quality Production

The Evolution of Teflon Flexible Hoses A Modern Manufacturing Perspective

In today’s industrial landscape, the demand for versatile and durable materials has never been higher. One of the standout innovations in this regard is Teflon, a brand name for polytetrafluoroethylene (PTFE), renowned for its exceptional properties, including high-temperature resistance, chemical inertness, and low friction. Teflon flexible hoses have become a staple in numerous applications, ranging from the chemical industry to food processing and aerospace.

Understanding Teflon Flexible Hoses

Teflon flexible hoses are engineered for transporting various fluids, gases, and solids while minimizing the risk of leaks and contamination. Unlike traditional rubber or metal hoses, Teflon hoses can withstand harsh environments easily due to their unique molecular structure, which is not only resistant to heat but also chemically stable against aggressive substances. They are typically reinforced with a braid of stainless steel, providing additional strength and durability.

The Manufacturing Process

The production of Teflon flexible hoses begins with the careful selection of raw materials. High-quality PTFE resin is sourced from trusted suppliers, ensuring that the final product meets stringent quality standards. The manufacturing process involves several key steps

1. Extrusion The PTFE resin is carefully fed into an extruder, where it is heated and forced through a die to create a smooth, continuous tube. This step is critical, as the quality of the extruded tube will directly impact the performance of the final product.

2. Braising After extrusion, the Teflon tubing is braided with stainless steel for reinforcement. This braiding is done with high precision to maintain the flexibility of the hose while significantly increasing its pressure tolerance.

teflon flex hose factory

3. Finishing Once braided, the hoses undergo various finishing processes. This may involve cutting the hoses to specific lengths, adding end fittings, and conducting pressure tests to ensure they can handle the intended operational pressures.

4. Quality Control Any reputable Teflon flexible hose factory ensures that rigorous quality control processes are in place. Samples from each batch are tested for standards such as flexibility, chemical resistance, durability, and pressure tolerance. This quality assurance process is crucial for industries where safety and reliability are paramount.

Applications of Teflon Flexible Hoses

Teflon flexible hoses find applications across a myriad of industries. In the chemical industry, they are invaluable for handling aggressive solvents and acids due to their chemical resistance. In the food and beverage sector, Teflon hoses are used in a variety of processes, ensuring that sanitary standards are met without compromising on performance. The aerospace industry also relies on Teflon hoses for their lightweight yet robust characteristics, suitable for high-performance systems.

The Future of Teflon Hose Manufacturing

As technology advances, the manufacturing processes for Teflon flexible hoses will continue to evolve. Innovations such as digital fabrication techniques and advanced material science could lead to even lower production costs and enhanced product performance. Additionally, sustainability practices are becoming increasingly vital in manufacturing, and Teflon hose factories are beginning to explore eco-friendly practices, including recycling and utilizing greener materials in production.

In conclusion, the Teflon flexible hose factory stands at the forefront of industrial innovation, producing essential components that enhance safety and efficiency across various fields. With ongoing advancements in technology and manufacturing processes, the future looks bright for Teflon hose production, ensuring that industries can rely on these exceptional products for years to come.

-

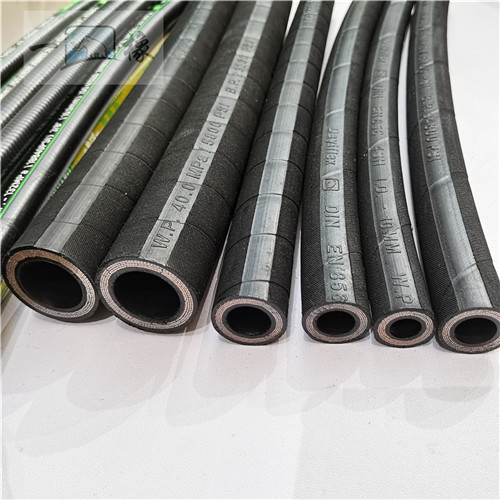

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025