1 月 . 20, 2025 04:36 Back to list

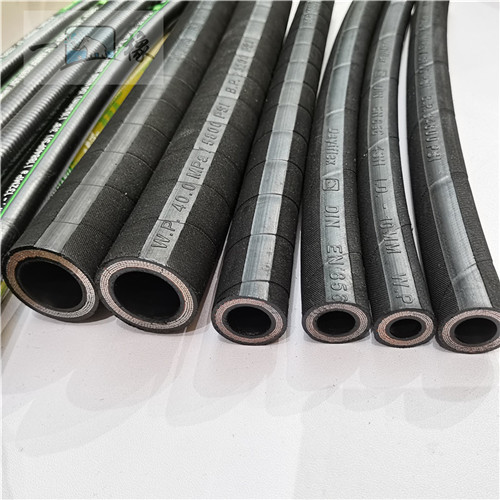

SAE100R2 AT DIN EN 853 2SN Black Cloth Cover Hydraulic Hose

SAE100R12 hydraulic hoses are quintessential in various industrial applications, renowned for their robustness and resilience in handling high-pressure levels and demanding work environments. This hydraulic hose is specifically designed to endure challenging pressure situations, making it an indispensable asset in industries ranging from construction to mining and agriculture. Understanding the intricacies of SAE100R12 can significantly enhance performance, safety, and operational efficiency.

The authoritativeness of SAE100R12 hoses is well-established, given their compliance with rigorous international standards. These hoses meet both SAE and ISO specifications, assuring users of their quality and performance. The widespread adoption of SAE100R12 hoses across various high-stakes industries is a testament to their reliability and efficiency. A crucial trust factor associated with SAE100R12 comes down to choosing the right manufacturer. With a plethora of manufacturers in the market, sourcing hoses from reputable companies that adhere to strict quality control protocols is vital. High-quality SAE100R12 hoses can significantly mitigate risks of premature failures and extend the service life of hydraulic systems. Feedback from industries utilizing SAE100R12 hoses is overwhelmingly positive. Users report a substantial increase in the durability and lifespan of machinery components when equipped with these hoses, resulting in lowered maintenance costs and operational downtime. The renowned resilience of these hoses also contributes to enhanced safety standards within work environments. In conclusion, SAE100R12 hydraulic hoses stand as a formidable component within any hydraulic system, backed by their sturdy construction and ability to perform under demanding conditions. As industries continue to evolve and demand more resilient solutions, SAE100R12 remains a cornerstone for ensuring fluid power is delivered efficiently and safely. By focusing on proper installation, regular maintenance, and sourcing from credible manufacturers, users can maximize the benefits and reliability that SAE100R12 hoses offer. The consistent track record of these hoses across diversified applications firmly positions them as a trusted choice in the hydraulic industry.

The authoritativeness of SAE100R12 hoses is well-established, given their compliance with rigorous international standards. These hoses meet both SAE and ISO specifications, assuring users of their quality and performance. The widespread adoption of SAE100R12 hoses across various high-stakes industries is a testament to their reliability and efficiency. A crucial trust factor associated with SAE100R12 comes down to choosing the right manufacturer. With a plethora of manufacturers in the market, sourcing hoses from reputable companies that adhere to strict quality control protocols is vital. High-quality SAE100R12 hoses can significantly mitigate risks of premature failures and extend the service life of hydraulic systems. Feedback from industries utilizing SAE100R12 hoses is overwhelmingly positive. Users report a substantial increase in the durability and lifespan of machinery components when equipped with these hoses, resulting in lowered maintenance costs and operational downtime. The renowned resilience of these hoses also contributes to enhanced safety standards within work environments. In conclusion, SAE100R12 hydraulic hoses stand as a formidable component within any hydraulic system, backed by their sturdy construction and ability to perform under demanding conditions. As industries continue to evolve and demand more resilient solutions, SAE100R12 remains a cornerstone for ensuring fluid power is delivered efficiently and safely. By focusing on proper installation, regular maintenance, and sourcing from credible manufacturers, users can maximize the benefits and reliability that SAE100R12 hoses offer. The consistent track record of these hoses across diversified applications firmly positions them as a trusted choice in the hydraulic industry.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025