8 月 . 16, 2024 10:31 Back to list

Reliable Suppliers for SAE 100R16 Hydraulic Hoses in China for Your Industrial Needs

Understanding SAE 100R16 Hydraulic Hoses A Comprehensive Guide for Suppliers in China

The hydraulic hose industry plays a critical role in various sectors, including construction, manufacturing, and automotive. Among the different types of hydraulic hoses, SAE 100R16 has garnered significant attention due to its robust performance and reliability. This article delves into the features of SAE 100R16 hoses, the demand in China, and how suppliers can effectively meet this demand.

Overview of SAE 100R16 Hydraulic Hoses

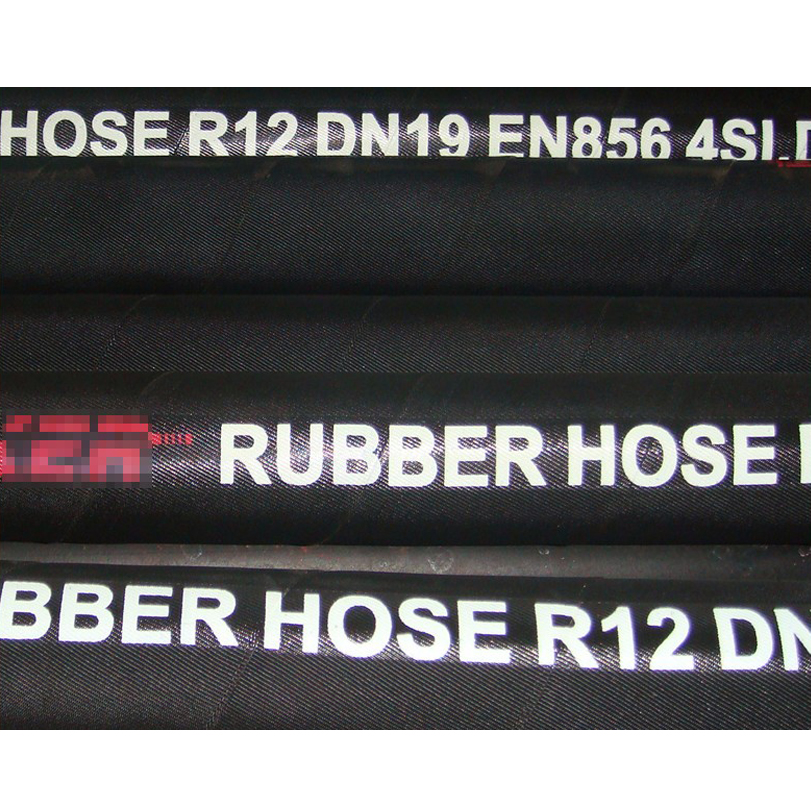

SAE 100R16 hoses are designed to handle high-pressure hydraulic applications. They are constructed with a synthetic rubber inner tube, reinforced with high-tensile steel wire, and covered with a durable abrasion-resistant outer layer. The construction ensures that these hoses can withstand tough working conditions, resisting factors such as temperature extremes, oil, and abrasion.

The specification of SAE 100R16 allows for a maximum working pressure of up to 4000 psi, depending on the hose size. This makes them ideal for heavy equipment in industries such as mining, agriculture, and transportation. Additionally, the versatility of SAE 100R16 hoses enables them to be used in various hydraulic systems, enhancing their demand in the market.

The Growing Demand for SAE 100R16 in China

China's rapid industrialization and urbanization have created a strong demand for hydraulic components, including hoses. With extensive construction projects, the manufacturing sector's growth, and advancements in agriculture, the need for high-quality hydraulic hoses has surged. As a result, suppliers of SAE 100R16 hoses are capitalizing on this market potential.

Chinese suppliers are increasingly focusing on quality assurance and compliance with international standards. They invest in advanced manufacturing techniques and materials to produce hoses that meet the rigorous demands of various industries. This focus on quality not only satisfies domestic needs but also opens up export opportunities to international markets.

Key Considerations for Suppliers

china sae100r16 supplier

For suppliers looking to enter or expand within the SAE 100R16 market in China, several key considerations must be taken into account

1. Quality Control Implementing stringent quality control processes is crucial. This includes testing the hoses for pressure, durability, and resistance to different environmental factors. Ensuring that the products meet ASTM and SAE standards will build credibility and trust among customers.

2. Market Research Understanding the specific needs of various industries is vital. Different sectors may require hoses with particular specifications. Conducting thorough market research can help suppliers tailor their products to meet these specific demands.

3. Partnerships and Networking Building strong relationships with manufacturers, distributors, and end-users can enhance market penetration. Participating in trade shows and industry conferences can provide valuable networking opportunities and increase visibility.

4. Sustainability Practices As industries lean towards sustainability, suppliers should consider eco-friendly practices in their production processes. This can include using recyclable materials and reducing waste, which can resonate well with environmentally conscious consumers.

5. Innovation Technological advancements are continually evolving the hydraulic hose market. Suppliers should be open to incorporating new technologies and materials that improve the performance and longevity of hydraulic hoses. Staying ahead of industry trends will help maintain a competitive edge.

Conclusion

The SAE 100R16 hydraulic hose market in China presents a wealth of opportunities for suppliers. By prioritizing quality, understanding customer needs, and adopting innovative practices, suppliers can effectively meet the growing demand in this sector. With the right strategies and focus, businesses can thrive in this competitive landscape, contributing to the broader growth of hydraulic technology in China and beyond.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025