8 月 . 15, 2024 09:30 Back to list

Reliable Supplier for Low Pressure Hydraulic Hoses to Meet Your Fluid Power Needs эффективно.

Low Pressure Hydraulic Hose Supplier A Comprehensive Guide

Hydraulic systems are an essential part of modern machinery and equipment, powering everything from construction machinery to agricultural vehicles. Among the various components that make up these systems, hydraulic hoses play a critical role in ensuring the efficient transfer of fluid. In particular, low pressure hydraulic hoses are designed for specific applications that require less stringent pressure tolerances. This article will explore the significance of low pressure hydraulic hoses, their applications, and what to look for in a reliable supplier.

Understanding Low Pressure Hydraulic Hoses

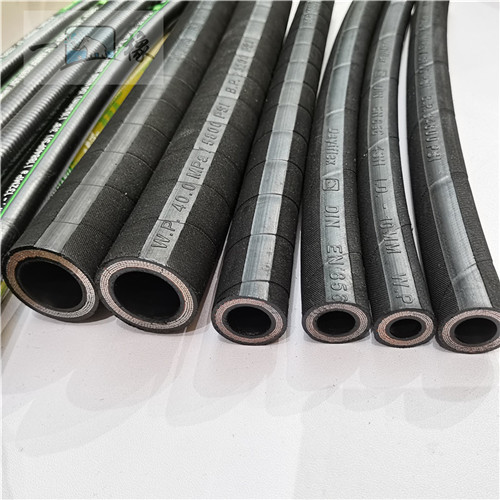

Low pressure hydraulic hoses are designed to operate under a higher flow rate but with low pressure levels. Typically, these hoses are constructed using synthetic rubber reinforced with textiles or steel, providing flexibility and durability while maintaining resistance to various environmental factors such as temperature changes, oil, and chemicals. They are engineered to handle applications with pressures generally within the range of 150 to 300 PSI, making them suitable for tasks where high pressure is not a critical requirement.

Applications of Low Pressure Hydraulic Hoses

Low pressure hydraulic hoses have a variety of applications across multiple industries. Common uses include

1. Agricultural Equipment In farming machinery, these hoses are often used for hydraulic systems that control implements and attachments that do not require high pressure, such as seeders and sprayers.

2. Material Handling Low pressure hoses are prevalent in conveyor belts and various handling equipment where the hydraulic systems control movements in a safe and efficient manner without the need for excessive pressure.

3. Automotive In vehicles, especially those designed for less demanding applications, low pressure hoses can be used for power steering systems, brake systems, and other hydraulic fluid transfer systems that operate under lower pressure settings.

low pressure hydraulic hose supplier

Choosing the Right Supplier

When it comes to sourcing low pressure hydraulic hoses, selecting the right supplier is crucial for ensuring quality and reliability. Here are some factors to consider

1. Product Variety A good supplier should offer a range of low pressure hydraulic hoses compatible with different applications. This ensures that you can find the right product that meets your specific needs.

2. Quality Assurance Look for suppliers who comply with industry standards and provide certifications for their products. High-quality hoses are essential for safety and performance in hydraulic systems.

3. Customization Options Depending on your application, you may require customized hoses. A reputable supplier should offer options for different lengths, fittings, and material specifications.

4. Technical Support The best suppliers provide excellent customer support, including technical assistance in selecting the right hose for your application and guidance on installation and maintenance practices.

5. Delivery and Logistics Consider the supplier's ability to deliver products in a timely manner. Fast delivery can be critical, especially in industries where downtime can lead to significant financial losses.

6. Pricing and Warranty Evaluate the pricing structures and warranties provided. Competitive pricing should not compromise the quality, and a solid warranty can provide confidence in the purchase.

Conclusion

Low pressure hydraulic hoses are vital components in various industrial applications, making them essential for many operations. By understanding their functions and applications and selecting a reliable supplier, businesses can ensure optimal performance and longevity from their hydraulic systems. Whether you are involved in agriculture, construction, or automotive industries, finding the right low pressure hydraulic hose supplier can make a significant difference in your operations.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025