1 月 . 24, 2025 05:21 Back to list

SAE 100 R7 Thermoplastic Hose

Quick disconnect hydraulic hose fittings are essential components in the fluid power industry, providing a seamless and efficient way to connect and disconnect hydraulic hoses without the need for tools. This feature is critical in applications where speed and efficiency are paramount, such as in construction, agriculture, and industrial settings.

From an expertise standpoint, quick disconnect hydraulic hose fittings require minimal training for effective use, thanks to their intuitive design. However, understanding the nuances of selecting the right fitting for a specific application is vital. Factors such as the type of fluid being used, the pressure levels, and the environmental conditions must be carefully considered to ensure compatibility and maximize performance. Professionals in the sector should stay abreast of the latest developments and standards in hydraulic technology, ensuring they specify products that enhance operational efficiency and safety. Authoritativeness in the field of hydraulic systems can be demonstrated by recognizing and adhering to industry standards and certifications. Products that meet these standards provide an assurance of quality and reliability. Organizations such as the International Organization for Standardization (ISO) and American National Standards Institute (ANSI) offer guidelines that inform the design and manufacturing processes of these components. Trustworthiness in quick disconnect hydraulic hose fittings is established by choosing manufacturers with a proven track record of quality and advancement. Customer reviews and case studies showcase real-world applications where these fittings have proven their worth. By investing in products from reputable companies, businesses not only secure durability and efficiency but also demonstrate their commitment to quality and safety. In conclusion, quick disconnect hydraulic hose fittings are an indispensable asset in various industrial applications. Their ability to merge speed, safety, and reliability makes them a favored choice among professionals. As technology evolves, these fittings are likely to become even more advanced, offering greater ease of use and enhanced safety features. Those in the industry must remain informed and judicious in their selection to harness the full potential of these vital components.

From an expertise standpoint, quick disconnect hydraulic hose fittings require minimal training for effective use, thanks to their intuitive design. However, understanding the nuances of selecting the right fitting for a specific application is vital. Factors such as the type of fluid being used, the pressure levels, and the environmental conditions must be carefully considered to ensure compatibility and maximize performance. Professionals in the sector should stay abreast of the latest developments and standards in hydraulic technology, ensuring they specify products that enhance operational efficiency and safety. Authoritativeness in the field of hydraulic systems can be demonstrated by recognizing and adhering to industry standards and certifications. Products that meet these standards provide an assurance of quality and reliability. Organizations such as the International Organization for Standardization (ISO) and American National Standards Institute (ANSI) offer guidelines that inform the design and manufacturing processes of these components. Trustworthiness in quick disconnect hydraulic hose fittings is established by choosing manufacturers with a proven track record of quality and advancement. Customer reviews and case studies showcase real-world applications where these fittings have proven their worth. By investing in products from reputable companies, businesses not only secure durability and efficiency but also demonstrate their commitment to quality and safety. In conclusion, quick disconnect hydraulic hose fittings are an indispensable asset in various industrial applications. Their ability to merge speed, safety, and reliability makes them a favored choice among professionals. As technology evolves, these fittings are likely to become even more advanced, offering greater ease of use and enhanced safety features. Those in the industry must remain informed and judicious in their selection to harness the full potential of these vital components.

Share

Next:

Latest news

-

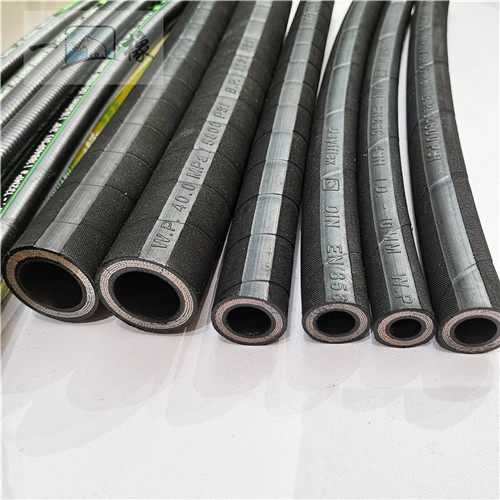

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025