2 月 . 10, 2025 22:11 Back to list

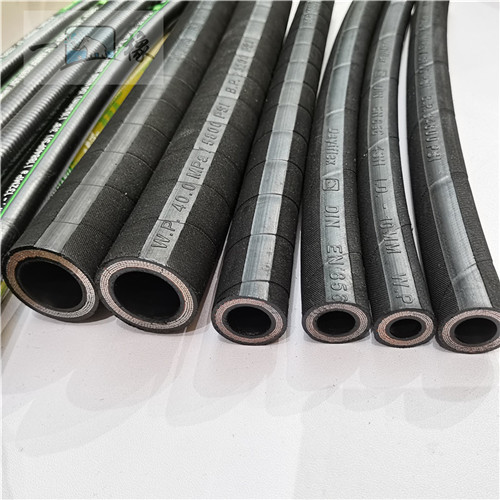

R16 Two layers of wire braided hydraulic hose

In the realm of hydraulic systems, the importance of high-quality hoses cannot be overstated. Among the different types of hoses available, the OEM yellow hydraulic hose stands out as a vital component, trusted by professionals globally. The significance of choosing the right hydraulic hose lies not only in ensuring the efficient operation of machinery but also in maintaining safety and minimizing downtime.

In cultivating authoritativeness, it is essential to note that leading manufacturers often adhere to international standards such as SAE, DIN, and ISO in their production processes. This adherence not only vouches for the reliability of the product but also enhances its global compatibility. Industry certifications and compliance with these standards underscore the commitment of these manufacturers to deliver top-tier products that can be trusted anywhere in the world. Trustworthiness is also reinforced by transparent manufacturing practices, where companies offer detailed documentation and data sheets for each hose model. These documents enable purchasers to make informed decisions based on critical factors such as burst pressure ratings, temperature range, and compatibility with different hydraulic fluids. Additionally, comprehensive customer support, including guidance on installation and maintenance, augments the trust that clients place in these hoses. While OEM yellow hydraulic hoses are integral to systems across various industries, their selection should be guided by specific application requirements. Consider factors such as pressure capacity, environmental conditions, flexibility, and the type of hydraulic fluid used. Consulting with experts or referring to technical guidelines can assist in choosing the appropriate hose for your particular needs, thus ensuring optimal performance and return on investment. In conclusion, the OEM yellow hydraulic hose embodies the convergence of engineering excellence and safety, making it a core component in the vast world of hydraulics. The blend of color-coded design, material durability, and stringent manufacturing standards propels these hoses to the forefront of reliability and performance. For industry professionals seeking to maximize equipment uptime and operational efficiency, these hoses represent a smart investment backed by expertise, authority, and trustworthiness.

In cultivating authoritativeness, it is essential to note that leading manufacturers often adhere to international standards such as SAE, DIN, and ISO in their production processes. This adherence not only vouches for the reliability of the product but also enhances its global compatibility. Industry certifications and compliance with these standards underscore the commitment of these manufacturers to deliver top-tier products that can be trusted anywhere in the world. Trustworthiness is also reinforced by transparent manufacturing practices, where companies offer detailed documentation and data sheets for each hose model. These documents enable purchasers to make informed decisions based on critical factors such as burst pressure ratings, temperature range, and compatibility with different hydraulic fluids. Additionally, comprehensive customer support, including guidance on installation and maintenance, augments the trust that clients place in these hoses. While OEM yellow hydraulic hoses are integral to systems across various industries, their selection should be guided by specific application requirements. Consider factors such as pressure capacity, environmental conditions, flexibility, and the type of hydraulic fluid used. Consulting with experts or referring to technical guidelines can assist in choosing the appropriate hose for your particular needs, thus ensuring optimal performance and return on investment. In conclusion, the OEM yellow hydraulic hose embodies the convergence of engineering excellence and safety, making it a core component in the vast world of hydraulics. The blend of color-coded design, material durability, and stringent manufacturing standards propels these hoses to the forefront of reliability and performance. For industry professionals seeking to maximize equipment uptime and operational efficiency, these hoses represent a smart investment backed by expertise, authority, and trustworthiness.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025