12 月 . 04, 2024 16:28 Back to list

oem thermoplastic hydraulic hose manufacturer

The Rise of OEM Thermoplastic Hydraulic Hose Manufacturers

In the ever-evolving landscape of industrial applications, the demand for high-quality hydraulic hoses has significantly increased. This upsurge can be attributed to the growing reliance on hydraulic systems across various sectors, including agriculture, construction, and manufacturing. Among the key players in this domain are OEM (Original Equipment Manufacturer) thermoplastic hydraulic hose manufacturers, who provide specialized solutions tailored to the specific needs of their customers.

Understanding Thermoplastic Hoses

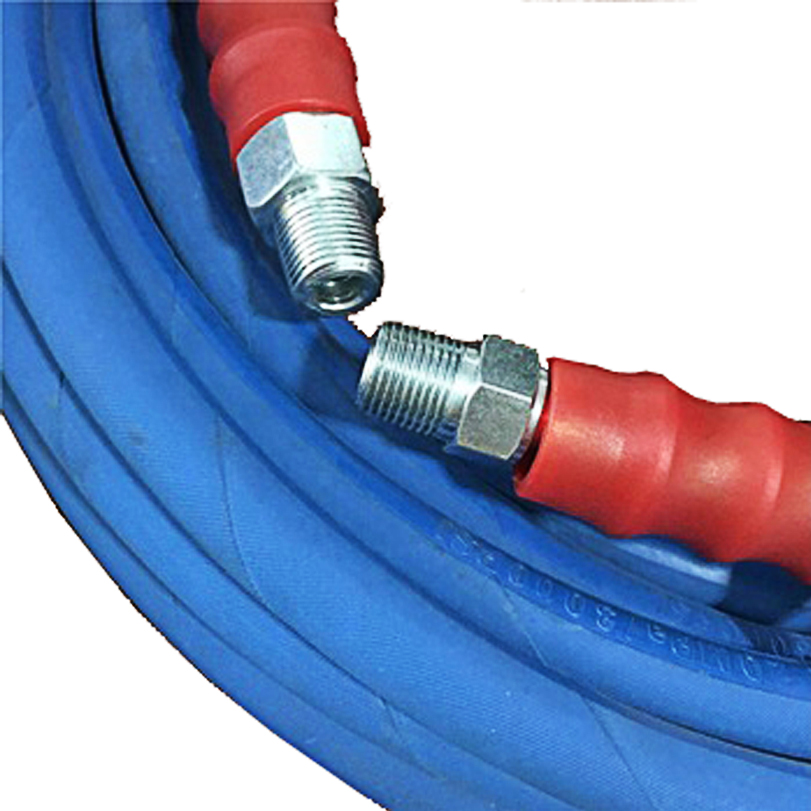

Thermoplastic hydraulic hoses are designed to transport hydraulic fluid under pressure in a variety of applications. Unlike traditional rubber hoses, thermoplastic hoses are made from a combination of polymers, which offer a range of advantages. These hoses are lightweight, flexible, and resistant to abrasion, making them ideal for environments where flexibility and durability are crucial.

The construction of thermoplastic hoses often incorporates multi-layer designs, allowing them to withstand extreme pressures while maintaining a compact profile. They are particularly advantageous in applications where space is limited or where reduced weight can enhance the overall efficiency of systems. Additionally, the chemical resistance of thermoplastic materials means they can handle a wider range of fluids without degrading.

The Role of OEM Manufacturers

OEM thermoplastic hydraulic hose manufacturers specialize in producing custom hydraulic hoses that meet the exact specifications of their clients

. These manufacturers play a crucial role in the supply chain, producing hoses that are essential for the functionality of machines and equipment. By offering tailored solutions, they ensure that companies can optimize their operations and improve overall efficiency.One of the significant advantages of working with OEM manufacturers is their ability to provide precise engineering input during product development. This collaboration often leads to the creation of hoses designed to withstand specific conditions, whether it be extreme temperatures, harsh chemicals, or unique pressure requirements. Such customization is vital for industries that cannot afford downtime or equipment failure.

Industry Applications

oem thermoplastic hydraulic hose manufacturer

OEM thermoplastic hydraulic hoses find applications in various industries. In construction, they are used in heavy machinery such as excavators, bulldozers, and lift trucks, where robust hydraulic systems are essential for performance. The flexibility and strength of thermoplastic hoses allow for smooth operation, even in the most challenging environments.

In the agricultural sector, these hoses are critical for equipment such as tractors, sprayers, and combines. The lightweight nature of thermoplastic hoses contributes to better fuel efficiency, while their durability ensures they can handle the demanding tasks associated with farming.

Moreover, the manufacturing industry relies heavily on hydraulic systems to power machinery, and custom thermoplastic hoses ensure that these systems operate at peak performance. Whether it’s for automotive assembly, metal forming, or plastic molding, having the right hydraulic hoses is essential for maintaining productivity and safety.

The Importance of Quality and Compliance

Quality and compliance are paramount when it comes to hydraulic hoses, particularly in high-stakes industries. OEM manufacturers emphasize rigorous testing and quality assurance processes to meet international standards. Certifications such as ISO 9001 ensure that the products not only meet but exceed industry requirements.

Additionally, the sustainability of the materials used in manufacturing thermoplastic hoses is becoming increasingly important. Many OEM manufacturers are now focusing on eco-friendly options, integrating sustainable practices into their production processes. This shift not only appeals to environmentally conscious companies but also aligns with emerging regulations aimed at reducing the environmental impact of industrial operations.

Conclusion

The landscape of OEM thermoplastic hydraulic hose manufacturing continues to expand, driven by the demand for customized, high-performance solutions across various industries. As technology advances, these manufacturers are likely to innovate further, integrating new materials and designs that will enhance performance and sustainability. In an era where efficiency and reliability are paramount, the role of OEM thermoplastic hydraulic hose manufacturers will remain critical in powering the machinery that drives our modern economy.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025