2 月 . 11, 2025 07:20 Back to list

oem smooth cover steel wire braided hydraulic hose

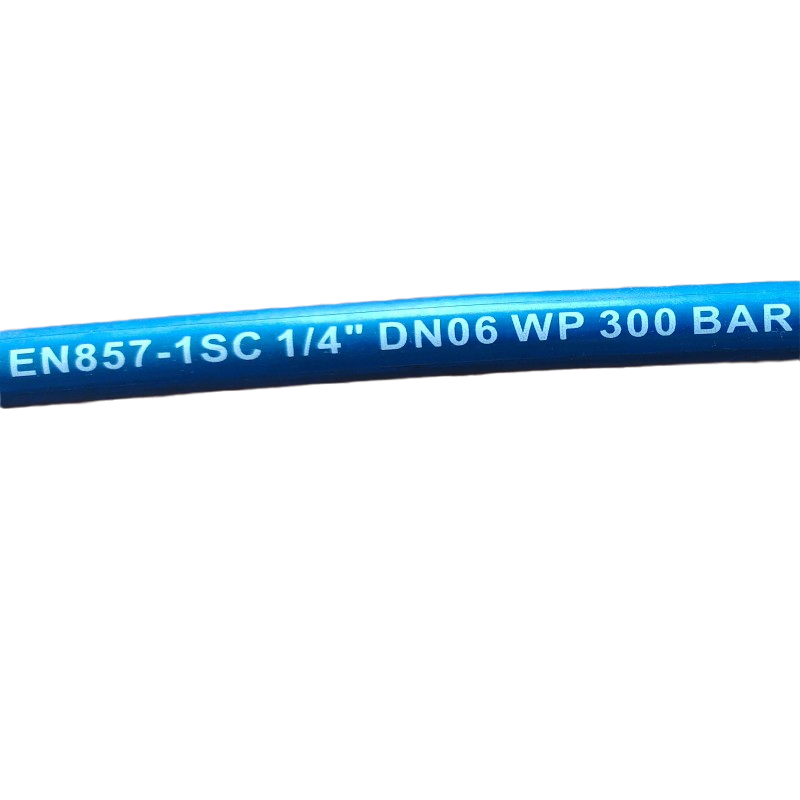

OEM smooth cover steel wire braided hydraulic hoses represent an essential component in various industrial machinery and automotive systems, providing efficient fluid conveyance under high-pressure conditions. The modern hydraulic hose industry increasingly emphasizes the integration of robust designs with innovative technology to ensure that hoses meet stringent safety, durability, and performance standards.

An often-overlooked benefit of these hoses lies in their resistance to oils and chemicals. Hydraulic systems often operate with fluids that can degrade materials over time. The outer smooth cover, combined with the inner material of the hose, offers a robust defense against such corrosive materials, ensuring longevity and reliability in demanding settings. From an authority perspective, the design and manufacture of OEM smooth cover steel wire braided hydraulic hoses are conducted under strict industry standards. Compliance with international guidelines, such as the Society of Automotive Engineers (SAE) standards or the International Organization for Standardization (ISO) certifications, ensures that these hoses provide reliable performance across various applications. This adherence not only establishes trust among manufacturers and users but also sets a benchmark for quality and safety in the industry. In practice, users have reported significant improvements in system performance by adopting high-quality OEM smooth cover steel wire braided hydraulic hoses. In heavy-duty machinery, these hoses have contributed to reducing downtimes caused by hose failures, ultimately enhancing productivity and operational efficiency. Similarly, in automotive applications, they ensure consistent performance and safety, critical factors given the intensive nature of vehicle operations. Selecting the right hydraulic hose supplier is crucial to harnessing these benefits. Trustworthy manufacturers prioritize quality and customer service, offering guidance in selecting the appropriate hose dimensions, pressure ratings, and construction materials to match specific application requirements. With the added value of customized solutions, users can maximize the performance and lifespan of their hydraulic systems. In conclusion, OEM smooth cover steel wire braided hydraulic hoses offer a comprehensive solution for industries demanding high reliability and performance under challenging conditions. By choosing these hoses, operators not only ensure superior fluid transfer but also safeguard their machinery and operations against potential failures, underscoring the importance of quality components in complex hydraulic systems.

An often-overlooked benefit of these hoses lies in their resistance to oils and chemicals. Hydraulic systems often operate with fluids that can degrade materials over time. The outer smooth cover, combined with the inner material of the hose, offers a robust defense against such corrosive materials, ensuring longevity and reliability in demanding settings. From an authority perspective, the design and manufacture of OEM smooth cover steel wire braided hydraulic hoses are conducted under strict industry standards. Compliance with international guidelines, such as the Society of Automotive Engineers (SAE) standards or the International Organization for Standardization (ISO) certifications, ensures that these hoses provide reliable performance across various applications. This adherence not only establishes trust among manufacturers and users but also sets a benchmark for quality and safety in the industry. In practice, users have reported significant improvements in system performance by adopting high-quality OEM smooth cover steel wire braided hydraulic hoses. In heavy-duty machinery, these hoses have contributed to reducing downtimes caused by hose failures, ultimately enhancing productivity and operational efficiency. Similarly, in automotive applications, they ensure consistent performance and safety, critical factors given the intensive nature of vehicle operations. Selecting the right hydraulic hose supplier is crucial to harnessing these benefits. Trustworthy manufacturers prioritize quality and customer service, offering guidance in selecting the appropriate hose dimensions, pressure ratings, and construction materials to match specific application requirements. With the added value of customized solutions, users can maximize the performance and lifespan of their hydraulic systems. In conclusion, OEM smooth cover steel wire braided hydraulic hoses offer a comprehensive solution for industries demanding high reliability and performance under challenging conditions. By choosing these hoses, operators not only ensure superior fluid transfer but also safeguard their machinery and operations against potential failures, underscoring the importance of quality components in complex hydraulic systems.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025