12 月 . 04, 2024 16:40 Back to list

OEM Parker Hydraulic Hose Fittings for Reliable and Efficient Fluid Transfer Solutions

Understanding OEM Parker Hydraulic Hose Fittings

Hydraulic systems form the backbone of numerous industrial applications, providing the necessary power to operate machinery and equipment efficiently. Among the key components of these systems are hydraulic hose fittings, which play a crucial role in ensuring fluid transfer and connection integrity. One prominent name in the industry is Parker Hannifin Corporation, a manufacturer well-known for producing high-quality hydraulic components, including OEM (Original Equipment Manufacturer) hydraulic hose fittings.

What Are Hydraulic Hose Fittings?

Hydraulic hose fittings are essential components used to connect hydraulic hoses to machines or systems. They ensure a secure and leak-proof connection between the hose and the equipment. The fittings come in various shapes and sizes, designed to accommodate different hose diameters and pressure ratings. They are typically made from durable materials such as steel or brass to withstand the rigorous demands of hydraulic applications.

Importance of OEM Hydraulic Hose Fittings

OEM hydraulic hose fittings are specifically designed to meet the original manufacturer's specifications. Using OEM parts is critical for ensuring optimal performance and safety in hydraulic systems. Here are a few reasons why OEM parts like Parker hydraulic hose fittings are important

1. Precision Fit OEM fittings are designed to fit perfectly with the hoses and equipment for which they are intended. This precise fit minimizes the risk of leaks and failures, contributing to the overall efficiency of the hydraulic system.

2. Quality Assurance OEM parts undergo rigorous testing to meet industry standards for quality and performance. By choosing Parker's OEM fittings, users can be confident that they are using reliable and durable components that will withstand harsh operating conditions.

3. Compatibility OEM fittings are designed to work seamlessly with other OEM parts. This compatibility reduces the likelihood of system failures due to mismatched components, which can lead to costly downtimes and repairs.

4. Warranty Protection Many manufacturers, including Parker, offer warranties on their OEM parts. By using these components, customers can protect their investments and ensure they receive support in case of any defects or performance issues.

5. Safety The integrity of hydraulic systems is paramount, as failures can lead to accidents and injuries. Using OEM fittings from reputable manufacturers like Parker ensures that safety standards are maintained, safeguarding both personnel and equipment.

Parker Hydraulic Hose Fittings A Brief Overview

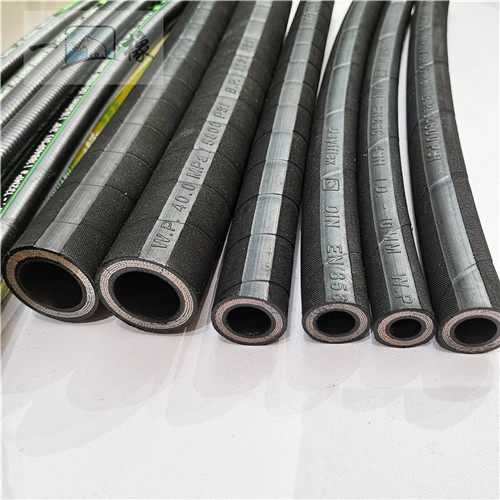

oem parker hydraulic hose fittings

Parker Hannifin is a leading manufacturer of motion and control technologies, and their hydraulic hose fittings are no exception. With a comprehensive range of designs, sizes, and materials, Parker offers a fitting for virtually every hydraulic application. Some popular types of Parker hydraulic hose fittings include

- JIC Fittings Joint Industry Council fittings are commonly used in hydraulic applications due to their reliable sealing capabilities.

- NPT Fittings National Pipe Thread fittings are ideal for connecting pipes and hoses where a tight seal is required.

- BSP Fittings British Standard Pipe fittings are often used in Europe and are available in both tapered and parallel threads.

- Push-to-Connect Fittings These are designed for easy installation and can be used in various applications, enhancing operational efficiency.

Maintenance and Inspection

To ensure the longevity and reliability of hydraulic hose fittings, regular maintenance and inspection are essential. Here are a few tips to keep in mind

- Routine Checks Regularly inspect fittings for signs of wear, corrosion, or leakage. Early detection of issues can prevent costly repairs and downtime.

- Proper Installation Follow the manufacturer’s guidelines for installation to ensure a secure fit. Over-tightening can damage fittings, while under-tightening can lead to leaks.

- Replace Worn Components Do not hesitate to replace old or damaged fittings with OEM parts to maintain system integrity.

Conclusion

In conclusion, OEM Parker hydraulic hose fittings are vital components that ensure the efficiency, safety, and reliability of hydraulic systems. Investing in high-quality fittings not only enhances system performance but also provides peace of mind for operators and manufacturers alike. For any industrial application relying on hydraulic power, choosing OEM components like those from Parker Hannifin is a decision grounded in quality, compatibility, and performance excellence. By prioritizing the use of OEM fittings, businesses can ensure their operations run smoothly and safely for years to come.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025