2 月 . 07, 2025 03:21 Back to list

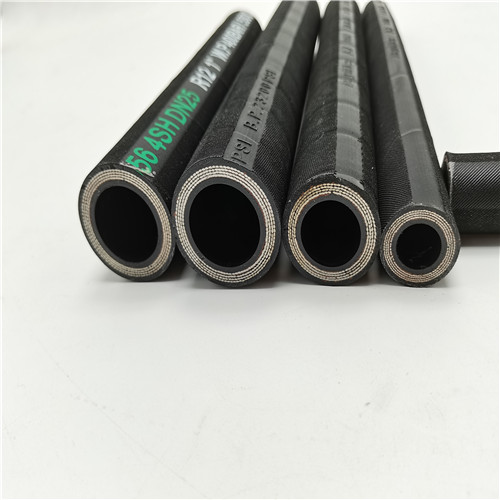

oem high pressure oil hose

In today's rapidly advancing industrial landscape, ensuring the reliability and durability of critical components is paramount. One such component, often overshadowed by more prominent machinery, is the OEM high pressure oil hose. Despite its seemingly modest role, this component is crucial for the optimal functioning of a variety of industrial systems, specifically those involving hydraulics and fluid dynamics.

Professionals selecting an OEM high pressure oil hose must also consider the hose’s compatibility with the fluids it transports. Different fluids can react with hose materials, potentially leading to degradation if improper materials are used. Therefore, the authoritative selection process involves thorough knowledge of both the fluid type and the material science governing hose construction. Trustworthiness in the manufacture and application of OEM high pressure oil hoses is built upon rigorous testing and compliance with international standards. Hoses undergo extensive evaluations, simulating extreme conditions to verify their performance and resilience. Certifications and compliance with standards such as SAE, DIN, and ISO provide assurance that these products meet global quality and safety benchmarks. The installation and maintenance practices of OEM high pressure oil hoses further augment their trustworthiness. Proper installation techniques ensure that the hoses maintain their performance capabilities, minimizing risks of leaks or bursts. Regular maintenance checks can preemptively detect wear signs, enabling timely interventions to forestall potential system failures. Rendering significant experience and expertise in handling these hoses promotes long-lasting service and optimal performance. In the sphere of after-market products, the reliance on OEM high pressure oil hoses guarantees compatibility and precise engineering, reflective of the original equipment specifications. This assures users of the maintained performance standards and integration ease with existing systems, embodying an authoritative solution for high-pressure applications. Ultimately, the OEM high pressure oil hose stands as a testament to engineering precision, where expertise and trustworthiness converge. Its role in sustaining the operational stability of heavy machinery reinstates its value in industries where performance reliability is non-negotiable. Therefore, investing in high-quality OEM hoses is not just about adhering to industry norms; it is about ensuring seamless operations and progressing towards industrial efficacy and safety.

Professionals selecting an OEM high pressure oil hose must also consider the hose’s compatibility with the fluids it transports. Different fluids can react with hose materials, potentially leading to degradation if improper materials are used. Therefore, the authoritative selection process involves thorough knowledge of both the fluid type and the material science governing hose construction. Trustworthiness in the manufacture and application of OEM high pressure oil hoses is built upon rigorous testing and compliance with international standards. Hoses undergo extensive evaluations, simulating extreme conditions to verify their performance and resilience. Certifications and compliance with standards such as SAE, DIN, and ISO provide assurance that these products meet global quality and safety benchmarks. The installation and maintenance practices of OEM high pressure oil hoses further augment their trustworthiness. Proper installation techniques ensure that the hoses maintain their performance capabilities, minimizing risks of leaks or bursts. Regular maintenance checks can preemptively detect wear signs, enabling timely interventions to forestall potential system failures. Rendering significant experience and expertise in handling these hoses promotes long-lasting service and optimal performance. In the sphere of after-market products, the reliance on OEM high pressure oil hoses guarantees compatibility and precise engineering, reflective of the original equipment specifications. This assures users of the maintained performance standards and integration ease with existing systems, embodying an authoritative solution for high-pressure applications. Ultimately, the OEM high pressure oil hose stands as a testament to engineering precision, where expertise and trustworthiness converge. Its role in sustaining the operational stability of heavy machinery reinstates its value in industries where performance reliability is non-negotiable. Therefore, investing in high-quality OEM hoses is not just about adhering to industry norms; it is about ensuring seamless operations and progressing towards industrial efficacy and safety.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025