2 月 . 07, 2025 04:07 Back to list

oem flexible hydraulic hose

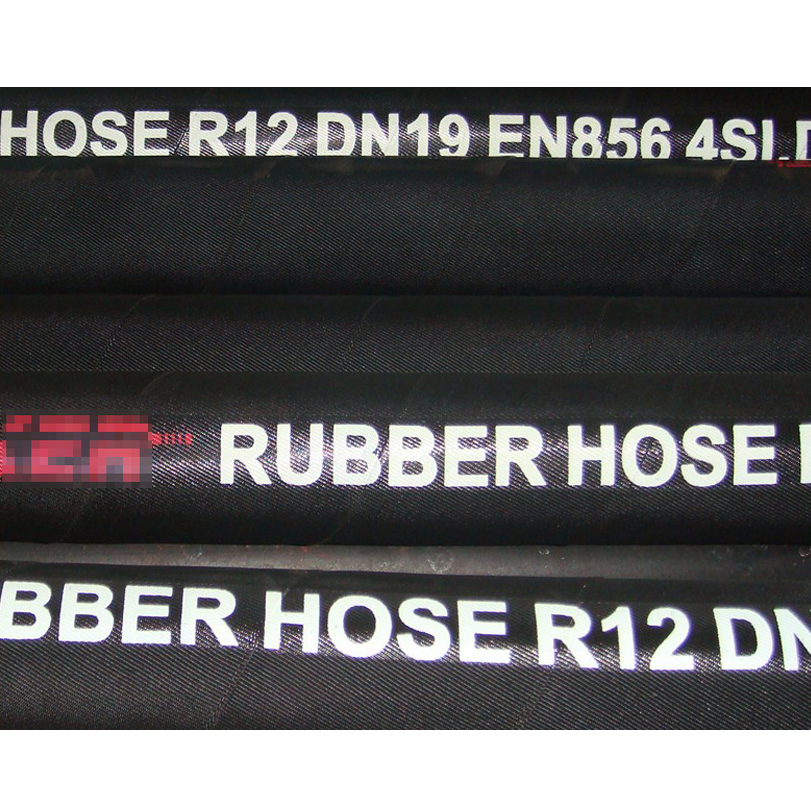

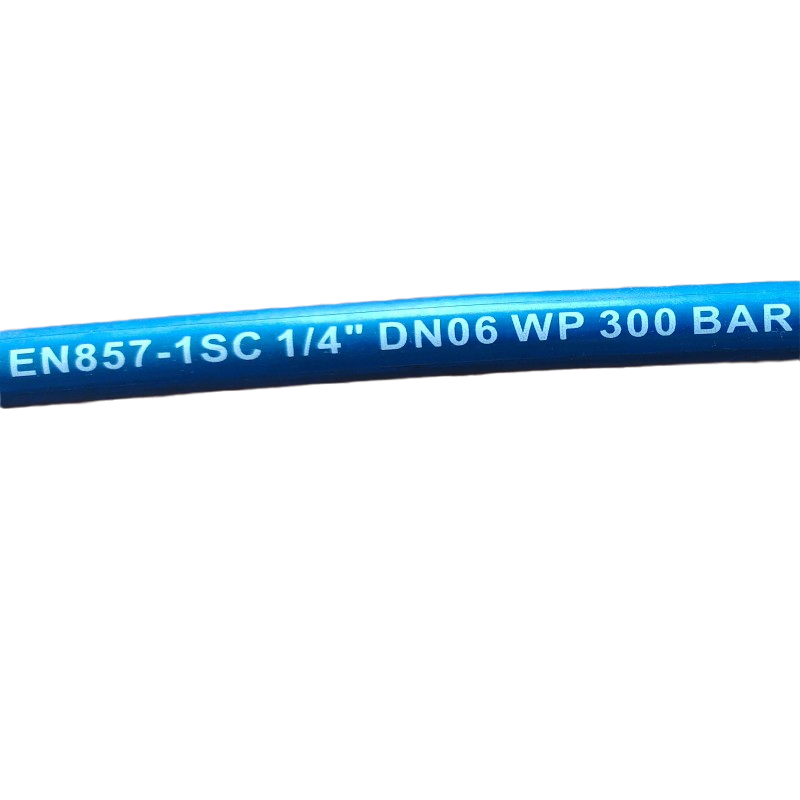

When it comes to sourcing OEM flexible hydraulic hoses, the critical factors often revolve around their reliability, adaptability, and durability. These hoses are integral in myriad industrial applications, from heavy machinery to automotive industries, where the seamless transmission of hydraulic fluids under varying pressures and temperatures is paramount. Understanding the nuances of these requirements can help industries enhance efficiency and resilience in their operations.

Trustworthiness in this domain involves selecting manufacturers and suppliers with a proven track record. Given the critical role that hydraulic hoses play in industrial operations, reliability is non-negotiable. Manufacturers who invest in technological advancements, rigorous testing, and quality assurance processes are often seen as leaders in the field. A robust warranty and support system also play into the trust factor, offering customers peace of mind regarding the lifecycle and performance of their hoses. Incorporating these well-engineered hoses into systems not only extends the lifespan of the machinery but also boosts overall efficiency. By minimizing potential failure points through high-quality and robust designs, operations can proceed with reduced disruptions. This reliability translates to economic benefits, as companies can reduce spending on repairs and downtime mitigation. Experienced engineers and procurement specialists recognize that choosing the right flexible hydraulic hoses involves more than just immediate cost considerations. It's an investment in operational stability and efficiency. Their expertise plays a crucial role in evaluating supplier credentials, material suitability, and compliance ratings, which are paramount in making informed decisions. In conclusion, OEM flexible hydraulic hoses offer substantial advantages in adaptability and durability, which are vital for a wide range of industrial applications. By focusing on the elements of expertise, authority, and trust, industries can secure reliable components that enhance their operations, ensuring safety, efficiency, and longevity. Opting for suppliers with a commitment to innovation and rigorous quality standards is key to harnessing the full potential of these hydraulic hoses.

Trustworthiness in this domain involves selecting manufacturers and suppliers with a proven track record. Given the critical role that hydraulic hoses play in industrial operations, reliability is non-negotiable. Manufacturers who invest in technological advancements, rigorous testing, and quality assurance processes are often seen as leaders in the field. A robust warranty and support system also play into the trust factor, offering customers peace of mind regarding the lifecycle and performance of their hoses. Incorporating these well-engineered hoses into systems not only extends the lifespan of the machinery but also boosts overall efficiency. By minimizing potential failure points through high-quality and robust designs, operations can proceed with reduced disruptions. This reliability translates to economic benefits, as companies can reduce spending on repairs and downtime mitigation. Experienced engineers and procurement specialists recognize that choosing the right flexible hydraulic hoses involves more than just immediate cost considerations. It's an investment in operational stability and efficiency. Their expertise plays a crucial role in evaluating supplier credentials, material suitability, and compliance ratings, which are paramount in making informed decisions. In conclusion, OEM flexible hydraulic hoses offer substantial advantages in adaptability and durability, which are vital for a wide range of industrial applications. By focusing on the elements of expertise, authority, and trust, industries can secure reliable components that enhance their operations, ensuring safety, efficiency, and longevity. Opting for suppliers with a commitment to innovation and rigorous quality standards is key to harnessing the full potential of these hydraulic hoses.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025