12 月 . 04, 2024 16:25 Back to list

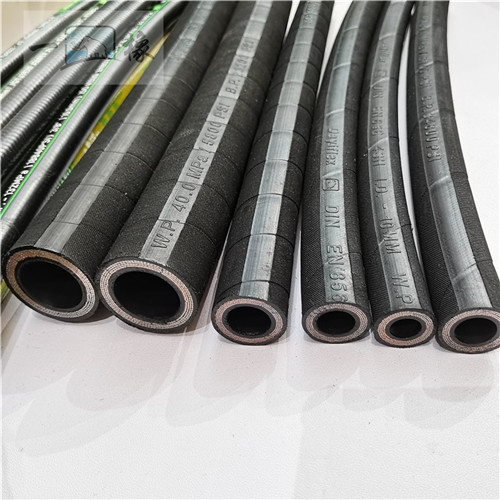

OEM Manufacturer of Black Wire Spiral Hydraulic Hoses for Various Applications

The Growing Demand for OEM Black Wire Spiral Hydraulic Hose Insights from the Factory Floor

In today's rapidly evolving industrial landscape, hydraulic hoses play a crucial role in a variety of applications, from construction and agriculture to manufacturing and beyond. Among the different types of hydraulic hoses available in the market, the OEM black wire spiral hydraulic hose stands out for its durability and performance. This article delves into the significance of this high-performance hose, its applications, and the factory processes involved in its production.

Understanding OEM Black Wire Spiral Hydraulic Hoses

OEM, or Original Equipment Manufacturer, refers to parts or products made by one company that are then marketed and sold by another company under its own brand name. The black wire spiral hydraulic hose is particularly noteworthy due to its robust construction, which typically features multiple layers of steel wire spirals that provide exceptional strength and flexibility. This design makes it suitable for high-pressure environments, allowing it to withstand the rigorous demands of various hydraulic systems.

The black color of the hose is not merely aesthetic; it serves practical purposes as well. The dark hue is resistant to UV rays, which helps extend the life of the hose when exposed to outdoor elements. Additionally, the ultra-durable construction minimizes the potential for wear and tear, making it a preferred choice for many businesses looking for reliability in their hydraulic systems.

Applications of Black Wire Spiral Hydraulic Hoses

One of the key aspects driving the demand for OEM black wire spiral hydraulic hoses is their versatility. These hoses are widely used in industries such as construction machinery, agricultural equipment, mining, and oil and gas industries. Specifically, they are crucial in equipment such as excavators, backhoes, tractors, and cranes, where high-pressure hydraulic systems are essential for operation.

Furthermore, their ability to perform under extreme conditions means that they are also used in applications that involve high temperatures or corrosive substances

. As industries continue to evolve and face new challenges, the demand for high-quality hydraulic hoses is only expected to grow.oem black wire spiral hydraulic hose factory

Manufacturing Processes in the Factory

The production of OEM black wire spiral hydraulic hoses involves several meticulous steps to ensure quality and reliability. The process begins with the selection of raw materials, where high-grade rubber compounds and steel wires are sourced. The rubber compounds are engineered to provide flexibility, tensile strength, and resistance to abrasions and chemicals.

Once the materials are prepared, the manufacturing process begins with extruding the rubber into the desired shapes and sizes. The steel wire spirals are then applied to reinforce the hose, creating multiple layers that enhance its pressure tolerance. Advanced machinery is employed to ensure precision in the layering and to prevent any weak points that could lead to hose failure.

Quality control is a vital aspect of the production process. Each batch of hoses undergoes rigorous testing, including pressure tests, flexibility assessments, and abrasion resistance checks. This stringent quality assurance guarantees that the final product meets industry standards and exceeds customer expectations.

Conclusion The Future of OEM Black Wire Spiral Hydraulic Hoses

As industries demand more from their equipment and hydraulic systems, the OEM black wire spiral hydraulic hose is positioned to play a significant role in this evolution. The combination of strength, versatility, and reliability makes it an indispensable component in various applications. With advancements in manufacturing technologies and materials, these hoses will continue to improve, offering even greater performance and safety features.

For businesses and industries reliant on hydraulic systems, investing in high-quality hoses is not just a choice but a necessity. As the factory floor adapts to meet the increasing demand, the future looks bright for OEM black wire spiral hydraulic hoses and the sectors they serve. Embracing innovation and maintaining stringent quality standards will ensure that these hoses remain at the forefront of hydraulic solutions for years to come.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025