8 月 . 16, 2024 10:51 Back to list

Manufacturers of LPG Rubber Hoses for Efficient and Reliable Fuel Delivery Solutions

Understanding LPG Rubber Hose Manufacturers and Their Importance in Industry

In today's world, where the demand for liquefied petroleum gas (LPG) is continually on the rise, ensuring safe and efficient transportation of this energy resource is paramount. One critical component in this logistical chain is the LPG rubber hose. The manufacturers of these specialized hoses play a vital role in various industries, including energy, automotive, and even culinary sectors.

The Functionality of LPG Rubber Hoses

LPG rubber hoses are specifically designed to transport liquefied petroleum gas from tanks to appliances or vehicles. Given the flammable nature of LPG, these hoses must meet strict safety standards to prevent leaks or ruptures that could lead to catastrophic incidents. These hoses typically consist of a synthetic rubber composite that can withstand high pressures and temperatures while resisting the corrosive properties of gas.

The primary functions of LPG rubber hoses include flexibility, resilience, and the ability to handle fluctuating pressures. The flexibility allows for easy maneuverability in tight spaces, while resilience ensures that the hoses can endure daily wear and tear over extended periods. Manufacturers focus on these properties to enhance the performance and safety of their products.

Manufacturing Process of LPG Rubber Hoses

The production of LPG rubber hoses is a complex process that involves several steps. It starts with the selection of high-quality raw materials tailored to withstand the specific conditions associated with LPG. Common materials used include synthetic rubbers like neoprene or EPDM (ethylene propylene diene monomer) due to their excellent resistance to heat and chemicals.

lpg rubber hose manufacturers

Once the materials are selected, the manufacturing process includes mixing the rubber compounds with various additives to enhance performance characteristics. Following this, the hoses are shaped using extrusion techniques to achieve the desired diameter and length. After shaping, the hoses undergo rigorous testing to ensure they meet safety standards established by industry regulations such as ISO and ASTM.

Quality control is a crucial aspect of the manufacturing process. Manufacturers often conduct tests for pressure endurance, leak resistance, and flexibility. This comprehensive testing ensures that the hoses can safely handle the high pressures and temperatures that accompany LPG transport.

Global Market and Manufacturers

The market for LPG rubber hoses has expanded significantly in recent years, driven by the increased use of LPG in heating and automotive applications globally. Numerous manufacturers are competing in this space, providing a wide range of products tailored to different industrial needs. Some of the leading manufacturers are recognized for their commitment to quality and innovation, which helps them maintain a competitive edge.

These companies often invest in research and development to create hoses that not only comply with existing safety standards but also incorporate advanced materials and technologies. This ensures that hoses remain efficient and durable, adapting to environmental changes while providing superior performance.

Conclusion

In conclusion, LPG rubber hose manufacturers play a critical role in the safe and efficient transportation of liquefied petroleum gas. By focusing on quality, safety, and innovation, these manufacturers contribute to the broader energy ecosystem, ensuring that LPG can be safely delivered to homes, businesses, and vehicles. As the demand for LPG continues to grow, so too will the importance of reliable and high-quality rubber hoses designed specifically for this purpose. With advancements in technology and an increasing emphasis on safety and efficiency, the future looks promising for LPG rubber hose manufacturing.

-

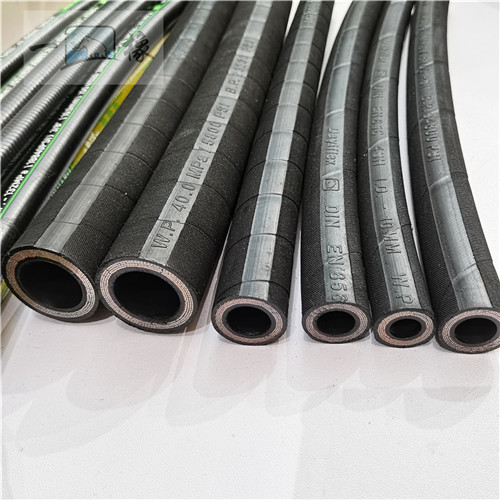

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025