8 月 . 18, 2024 00:51 Back to list

Leading Manufacturers of OEM Thermoplastic Hose SAE 100 R7 for Various Industrial Applications

OEM Thermoplastic Hose SAE 100R7 A Comprehensive Overview of Manufacturers

The demand for high-performance hoses in various industries has witnessed significant growth over the years, particularly for thermoplastic hoses. Among the many standards designed to ensure safety and reliability, SAE 100R7 is one of the most recognized. This standard outlines the specifications for thermoplastic hoses used in hydraulic systems, which are essential in sectors such as construction, agriculture, and manufacturing. In this article, we will delve into the features of SAE 100R7 thermoplastic hoses and an overview of the manufacturers involved in producing these vital components.

Understanding SAE 100R7 Thermoplastic Hose

SAE 100R7 hoses are designed to handle hydraulic fluids at higher pressures. They are typically made from thermoplastic materials such as nylon or polyester, which contributes to their flexibility, lightweight nature, and resistance to abrasion and chemicals. This makes them ideal for various applications, including fluid transfer in both mobile and stationary equipment.

One of the key advantages of thermoplastic hoses, particularly those meeting the SAE 100R7 standard, is their operating temperature range. They can maintain performance in a broader spectrum of temperatures compared to rubber hoses, making them suitable for use in both hot and cold environments. Additionally, the smooth inner surface of these hoses minimizes the risk of fluid buildup, enhancing overall efficiency.

Key Features of SAE 100R7 Hoses

1. Flexibility The inherent properties of thermoplastic materials provide excellent flexibility, allowing these hoses to be routed through tight spaces and around obstacles without compromising their structural integrity.

2. Lightweight Compared to rubber hoses, thermoplastic hoses are lighter, which can lead to reduced system weight and improved handling during installation and operation.

3. Chemical Resistance Thermoplastic hoses are resistant to many chemicals and oils, making them ideal for hydraulic applications across various industries.

oem thermoplastic hose sae100r7 manufacturers

4. Pressure and Temperature Ratings SAE 100R7 hoses are rated for medium pressure applications, typically up to 3000 psi. They operate effectively in temperature ranges from -40°F to +190°F, ensuring versatility in performance.

Leading Manufacturers of SAE 100R7 Thermoplastic Hoses

The market is flooded with numerous manufacturers producing SAE 100R7 thermoplastic hoses, each with its own unique offerings cater to various needs. Some notable manufacturers include

1. Parker Hannifin Known for their extensive range of hydraulic solutions, Parker produces high-quality thermoplastic hoses that meet the SAE 100R7 standard. Their commitment to innovation has made them a leader in the industry.

2. Gates Corporation Gates offers a variety of thermoplastic hose options, including those compliant with SAE 100R7. Their products are known for durability and reliability, backed by rigorous testing and quality assurance.

3. Continental With a strong presence in the global market, Continental manufactures hoses that meet a wide array of specifications. Their SAE 100R7 hoses are designed to provide long-lasting performance in demanding environments.

4. Novaflex Specializing in flexible hose solutions, Novaflex’s thermoplastic hoses are tailored for industrial applications. Their emphasis on performance and safety is a differentiating factor in their production.

5. Sun-Source Offering a range of thermoplastic hoses, Sun-Source combines quality materials with expert engineering to create hoses that exceed industry standards, including SAE 100R7.

In summary, SAE 100R7 thermoplastic hoses are essential components in many hydraulic applications, providing flexibility, lightweight solutions, and high performance across various industry sectors. With numerous manufacturers contributing to the market, choosing the right hose depends on specific application requirements, performance criteria, and industry standards. As industries continue to evolve, so too will the innovations in hose manufacturing, ensuring that high-quality, reliable hoses remain readily available to meet the ever-growing demands of modern applications.

-

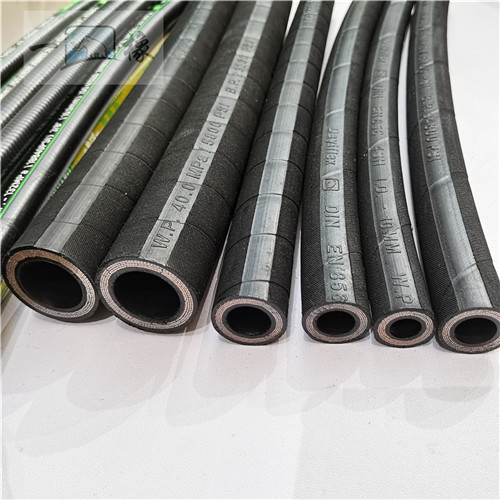

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025