1 月 . 06, 2025 19:20 Back to list

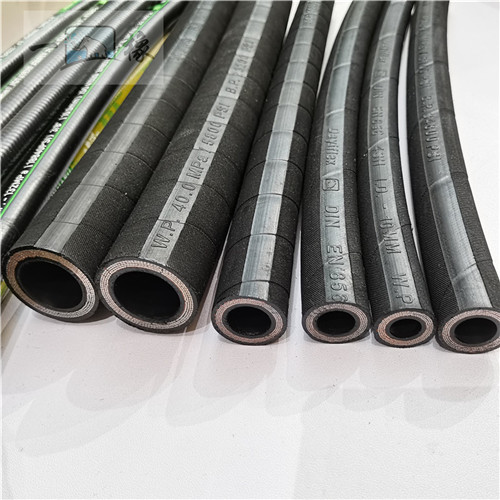

SAE 100R2 AT DIN EN 853 2SN Black Smooth Cover Hydraulic Hose

Hydraulic rubber hoses are indispensable components in the vast realm of industrial machinery, offering critical solutions for fluid conveyance in applications ranging from construction to aerospace. These hoses, designed with precision engineering and robust materials, ensure seamless functionality and enhance the longevity of the equipment they are integrated into.

Understanding the unique composition of hydraulic rubber hoses is fundamental to their application and longevity. Crafted from synthetic rubber, these hoses are designed to withstand extreme temperatures and pressures, making them ideal for a myriad of environmental conditions. The reinforced layers, typically comprised of braided or spiral stainless steel, provide the necessary resilience against mechanical stress and external abrasions, ensuring that the fluid dynamics within remain stable and efficient.

Professionally speaking, the selection process for the appropriate hydraulic rubber hose should be meticulous. It involves assessing several factors, including the type of fluid being transferred, the temperature conditions, pressure requirements, and environmental exposure. This selection process is critical for ensuring operational effectiveness, preventing downtime, and extending the life span of the machinery.

In industries like mining and construction, where rugged conditions are a daily challenge, hydraulic rubber hoses offer reliability and durability. These environments demand hoses that can endure continuous flexing and bending without compromising the structural integrity. Specialized designs, such as those with Teflon linings, provide added chemical resistance, further expanding the functionality of the hoses across diverse industrial applications.

Expertise in installation and maintenance is equally crucial. Proper installation involves ensuring that connectors and fittings are precisely attached to avoid leaks and maintain pressure stability. Regular maintenance checks should include inspections for signs of wear, such as cracks or bulges, and prompt replacement of damaged hoses. Adherence to these best practices not only optimizes machine performance but also significantly contributes to workplace safety.

hydraulic rubber hose

The authoritativeness of hydraulic rubber hose manufacturers plays a pivotal role in the reliability of the products. Reputable manufacturers adhere to stringent international standards and certifications, such as SAE and DIN, which testify to the quality and safety of their hoses. Collaborating with such manufacturers ensures that industries have access to products that meet the highest benchmarks of performance and durability.

Trustworthiness in the scope of hydraulic rubber hoses is cultivated through transparent communication and customer support. Providers who offer detailed product specifications, application guidelines, and technical support help foster a sense of confidence in the user. Additionally, warranties and after-sales services are critical components that reinforce the trust between the manufacturer and the consumer.

Advancements in technology continue to revolutionize the landscape of hydraulic rubber hoses. Developments in materials science and engineering have led to the creation of hoses that are lighter, more flexible, and capable of withstanding higher pressures. These innovations are particularly beneficial in applications where space and weight constraints are significant considerations, such as in aerospace engineering.

In summary, hydraulic rubber hoses serve as vital conduits in the functioning of complex machinery across various industries. Their design, characterized by layers of robust materials, supports high efficiency under demanding conditions. Professionals engaged in the selection, installation, and maintenance of these hoses must possess a thorough understanding and expertise to optimize their application. By partnering with authoritative and trustworthy manufacturers, industries can ensure access to products that promise reliability and performance excellence, thus maintaining the integrity and safety of their operations. As technology advances, hydraulic rubber hoses continue to evolve, offering enhanced solutions that meet the growing demands of industrial innovation.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025