1 月 . 22, 2025 05:35 Back to list

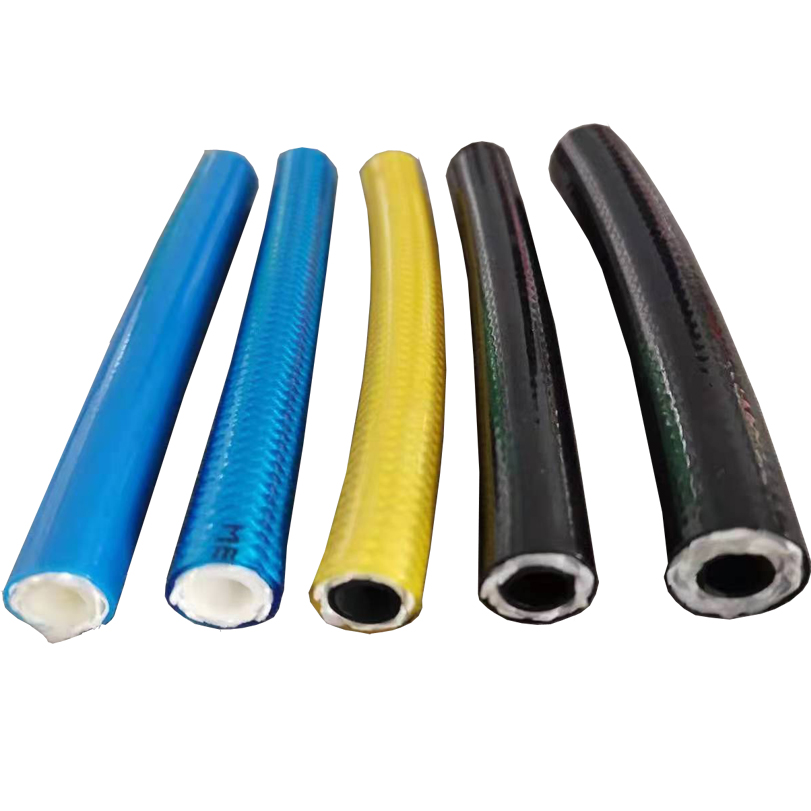

EN856 4SP Black smooth Cover Hydraulic Hose

Hydraulic hose fittings are integral components in a wide range of industrial and commercial machinery, providing essential connections that ensure the fluid conveyance system operates efficiently. Understanding their role and function is crucial for anyone involved in hydraulic systems, from novice engineers to seasoned technicians.

Trustworthiness is established through consistent performance and adherence to quality standards. When procuring hydraulic hose fittings, it is advisable to choose reputable manufacturers who are certified and known for rigorous testing and quality assurance processes. Reputable brands not only guarantee the durability and reliability of their products but also adhere to environmental and safety guidelines. This assurance fosters trust among buyers and end-users, preventing costly failures and enhancing the sustained performance of hydraulic systems. In the dynamic landscape of hydraulic systems, continuous learning remains paramount. With emerging trends such as eco-friendly fittings and the integration of sensors for predictive maintenance, staying informed about the latest innovations is key to optimizing system performance. Additionally, engaging with online forums and communities can provide valuable insights and collective problem-solving approaches, enriching one's knowledge and application strategies. End-users often underestimate the impact of hydraulic hose fittings on the entire system. In essence, these small components are the unsung heroes, playing a vital role in system integrity and performance. Therefore, investing time in understanding their proper selection, installation, and maintenance can lead to significant improvements in operational efficiency and longevity of hydraulic systems. Ultimately, the success in utilizing hydraulic hose fittings lies in the blend of experience, expertise, authoritativeness, and trustworthiness. By embracing these pillars, one can navigate the complexities of hydraulic systems, tailoring solutions that meet precise needs and enhance the overall productivity and safety of their operations.

Trustworthiness is established through consistent performance and adherence to quality standards. When procuring hydraulic hose fittings, it is advisable to choose reputable manufacturers who are certified and known for rigorous testing and quality assurance processes. Reputable brands not only guarantee the durability and reliability of their products but also adhere to environmental and safety guidelines. This assurance fosters trust among buyers and end-users, preventing costly failures and enhancing the sustained performance of hydraulic systems. In the dynamic landscape of hydraulic systems, continuous learning remains paramount. With emerging trends such as eco-friendly fittings and the integration of sensors for predictive maintenance, staying informed about the latest innovations is key to optimizing system performance. Additionally, engaging with online forums and communities can provide valuable insights and collective problem-solving approaches, enriching one's knowledge and application strategies. End-users often underestimate the impact of hydraulic hose fittings on the entire system. In essence, these small components are the unsung heroes, playing a vital role in system integrity and performance. Therefore, investing time in understanding their proper selection, installation, and maintenance can lead to significant improvements in operational efficiency and longevity of hydraulic systems. Ultimately, the success in utilizing hydraulic hose fittings lies in the blend of experience, expertise, authoritativeness, and trustworthiness. By embracing these pillars, one can navigate the complexities of hydraulic systems, tailoring solutions that meet precise needs and enhance the overall productivity and safety of their operations.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025