12 月 . 04, 2024 16:28 Back to list

high pressure thermoplastic hose manufacturer

High Pressure Thermoplastic Hose A Comprehensive Overview

In today’s rapidly evolving industrial landscape, the demand for efficient and reliable fluid transfer solutions is paramount. High pressure thermoplastic hoses have emerged as a critical component in various sectors, including agriculture, construction, mining, and manufacturing, due to their flexibility, durability, and resistance to harsh chemicals. Understanding the significance of these hoses, their manufacturing process, and their applications will shed light on why they are an indispensable tool for many industries.

What is High Pressure Thermoplastic Hose?

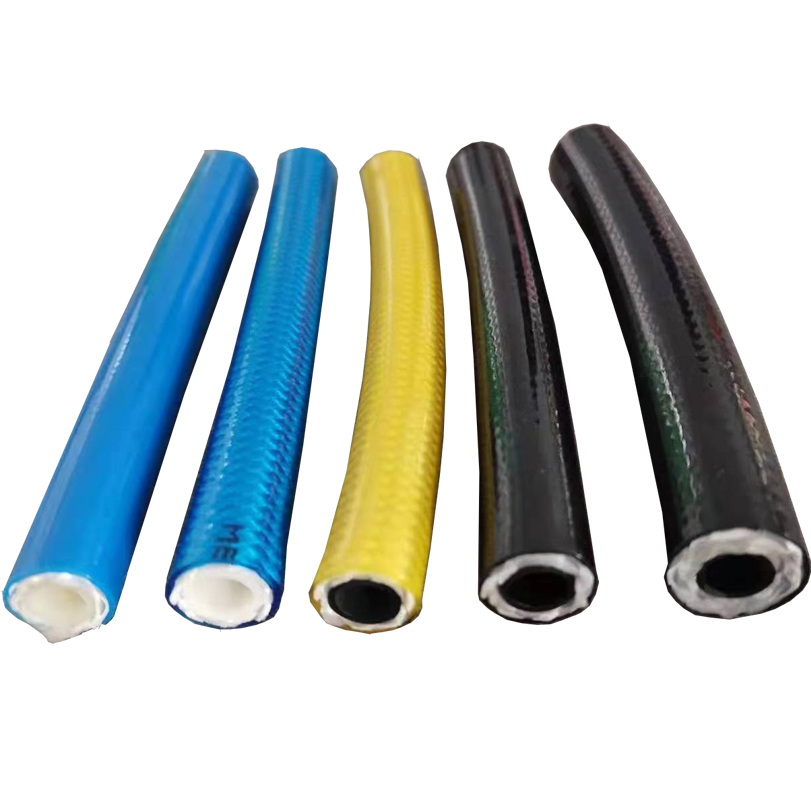

High pressure thermoplastic hose is specifically designed to withstand high fluid pressures, making them ideal for applications where peak performance and safety are crucial. These hoses are typically made from thermoplastic materials, such as polyester, nylon, or polyether, which provides them with enhanced resistance to chemical corrosion, UV radiation, and abrasion compared to traditional rubber hoses.

Advantages of Thermoplastic Hoses

One of the primary benefits of high pressure thermoplastic hoses is their lightweight nature, which makes them easier to handle and install compared to metal or rubber alternatives. This lightweight characteristic significantly reduces labor costs and enhances operational efficiency. Moreover, their superior flexibility allows them to bend and maneuver around obstacles easily, which is especially beneficial in tight working spaces.

Another key advantage is their resilience against extreme temperatures. High pressure thermoplastic hoses can operate effectively in a wide range of temperatures, from very low to very high, making them suitable for various environments. Additionally, their ability to resist degradation from chemicals makes them essential in industries involving aggressive fluids, such as oil and gas or chemical processing.

Manufacturing Process

The manufacturing of high pressure thermoplastic hoses involves several critical steps to ensure quality and performance. It begins with material selection, where manufacturers choose high-grade thermoplastic polymers based on the specific application requirements. Next, the hoses are extruded through precise molds to achieve the desired diameter and length.

high pressure thermoplastic hose manufacturer

Following extrusion, the hoses undergo a thorough quality control process, which includes pressure testing to ensure they can withstand the defined limits without failing. Reinforcement materials, such as braided or spiral wound yarns, are integrated to enhance the hoses' strength. Finally, the hoses are cut to length, fitted with appropriate connectors, and tested again to guarantee total compliance with industry standards.

Applications of High Pressure Thermoplastic Hoses

High pressure thermoplastic hoses are versatile and can be utilized across various sectors. In the agricultural field, they play a vital role in irrigation systems, enabling efficient water transfer while withstanding high pressures. In construction, these hoses are commonly used in hydraulic systems and to operate machinery, where reliability is critical for safety and productivity.

The mining industry relies on these hoses for transferring slurry and other abrasive materials due to their exceptional durability. Similarly, in the automotive sector, high pressure thermoplastic hoses are used in fuel systems and as part of the cooling processes, where performance under pressure is essential.

Choosing the Right Manufacturer

When selecting a high pressure thermoplastic hose manufacturer, it is essential to consider several factors. Look for a company that specializes in high-pressure hoses and boasts a proven track record of quality. Certifications such as ISO 9001 can indicate a commitment to quality management systems, while industry-specific certifications can ensure product compliance with necessary regulations.

Customer service is another crucial aspect to consider. A reliable manufacturer should offer support before, during, and after the sale, helping clients select the right hoses for their applications and providing prompt assistance for any issues that arise.

Conclusion

High pressure thermoplastic hoses are a vital resource in numerous industrial applications due to their lightweight, flexible, and durable nature. They offer unparalleled resistance to harsh chemicals, extreme temperatures, and high pressures, making them a preferred choice over traditional rubber hoses. By choosing a reputable manufacturer, industries can ensure optimum performance and reliability, leading to enhanced productivity and safety in their operations. As various sectors continue to evolve and face new challenges, the importance of high pressure thermoplastic hoses will undoubtedly grow, contributing to greater efficiency in fluid transfer solutions.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025