2 月 . 16, 2025 16:47 Back to list

high pressure thermoplastic hose factory

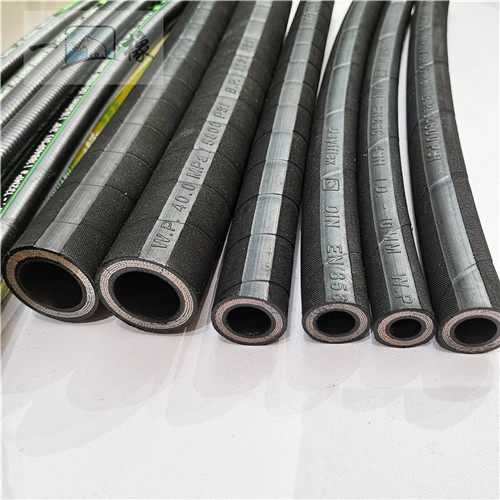

In the fast-paced world of industrial applications, selecting the right components can significantly impact performance, safety, and efficiency. One such crucial component is the high-pressure thermoplastic hose, extensively used across various sectors, including agriculture, construction, marine, and more. As factories worldwide prioritize durability and high performance, understanding the operations and expertise behind leading high-pressure thermoplastic hose factories can provide a competitive edge.

Trustworthiness is further reinforced by transparent business practices. Leading factories keep an open line of communication with their clients, often providing customized solutions that cater to the unique needs of each project. They encourage customer feedback and constantly refine their products based on field performance reports. Moreover, many of these factories offer comprehensive support and services, including installation guidance, troubleshooting, and after-sales support, ensuring the hoses perform optimally after leaving the factory floor. Environmental responsibility is another facet where reputable factories excel. As global industries pivot towards sustainability, the production processes have also evolved. Factories invest in green technologies that reduce emissions and waste. This not only aligns with global ecological standards but also appeals to eco-conscious clients. The development of recyclable thermoplastic materials demonstrates their commitment to environmental stewardship without compromising on hose performance. For those in search of reliable high-pressure thermoplastic hose suppliers, choosing one with a proven track record of excellence is essential. Factories that can merge experience, expertise, credibility, and open, honest client interactions serve as invaluable partners in business. Their expertise reduces downtime and enhances productivity, providing peace of mind that their products can be relied upon in critical applications. In conclusion, the world of high-pressure thermoplastic hose manufacturing is a robust field characterized by innovation, quality, and reliability. As these factories continue to advance, they not only meet the demands of today's industries but also set the benchmark for future developments, ensuring safer, more efficient, and sustainable solutions for industrial applications worldwide.

Trustworthiness is further reinforced by transparent business practices. Leading factories keep an open line of communication with their clients, often providing customized solutions that cater to the unique needs of each project. They encourage customer feedback and constantly refine their products based on field performance reports. Moreover, many of these factories offer comprehensive support and services, including installation guidance, troubleshooting, and after-sales support, ensuring the hoses perform optimally after leaving the factory floor. Environmental responsibility is another facet where reputable factories excel. As global industries pivot towards sustainability, the production processes have also evolved. Factories invest in green technologies that reduce emissions and waste. This not only aligns with global ecological standards but also appeals to eco-conscious clients. The development of recyclable thermoplastic materials demonstrates their commitment to environmental stewardship without compromising on hose performance. For those in search of reliable high-pressure thermoplastic hose suppliers, choosing one with a proven track record of excellence is essential. Factories that can merge experience, expertise, credibility, and open, honest client interactions serve as invaluable partners in business. Their expertise reduces downtime and enhances productivity, providing peace of mind that their products can be relied upon in critical applications. In conclusion, the world of high-pressure thermoplastic hose manufacturing is a robust field characterized by innovation, quality, and reliability. As these factories continue to advance, they not only meet the demands of today's industries but also set the benchmark for future developments, ensuring safer, more efficient, and sustainable solutions for industrial applications worldwide.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025