2 月 . 13, 2025 08:42 Back to list

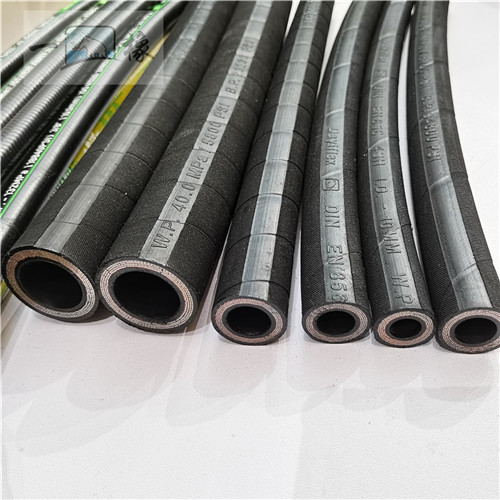

DIN-EN 857 1SC one layer wrapped cover hydraulic hose

The high pressure oil hose plays a pivotal role in a plethora of industries, from automotive to aviation, and its manufacturing is critical to ensuring both safety and efficiency. As a seasoned expert in the field of industrial component manufacturing, I have had the privilege of visiting multiple high pressure oil hose factories and delving into the nuanced process that underscores the production of these essential components.

Environmental sustainability is another vital facet of the manufacturing process. Many top-tier factories emphasize eco-friendly production by minimizing waste, recycling materials where feasible, and reducing emissions. By adhering to international environmental standards, these factories not only preserve natural resources but also underscore their commitment to sustainable practices—thereby enhancing their trustworthiness and authority. The question of trustworthiness in a high pressure oil hose factory extends beyond just product quality—it encompasses the entire customer interaction experience. Leading manufacturers often provide comprehensive customer support, from pre-purchase consultations to post-installation service. Experienced engineers are ready to advise clients on appropriate hose specifications for their particular applications, ensuring that every customer receives a product tailor-made to meet their unique needs. Moreover, these factories often sponsor training and provide detailed documentation to help customers maximize the lifespan and efficiency of their hoses. By empowering customers with knowledge, the manufacturers aren't just selling products; they’re cultivating long-term relationships built on trust and reliability. In conclusion, the manufacture of high pressure oil hoses is a complex yet fascinating process, marked by a blend of expert knowledge, precise craftsmanship, and unwavering dedication to safety and quality. Factories that prioritize these aspects establish themselves as leaders in the industry, earning them the respected status they hold in the market. For any business in need of high pressure oil hoses, understanding the intricacies of production and the commitment to excellence that these factories embody is essential in making the most informed purchasing decision.

Environmental sustainability is another vital facet of the manufacturing process. Many top-tier factories emphasize eco-friendly production by minimizing waste, recycling materials where feasible, and reducing emissions. By adhering to international environmental standards, these factories not only preserve natural resources but also underscore their commitment to sustainable practices—thereby enhancing their trustworthiness and authority. The question of trustworthiness in a high pressure oil hose factory extends beyond just product quality—it encompasses the entire customer interaction experience. Leading manufacturers often provide comprehensive customer support, from pre-purchase consultations to post-installation service. Experienced engineers are ready to advise clients on appropriate hose specifications for their particular applications, ensuring that every customer receives a product tailor-made to meet their unique needs. Moreover, these factories often sponsor training and provide detailed documentation to help customers maximize the lifespan and efficiency of their hoses. By empowering customers with knowledge, the manufacturers aren't just selling products; they’re cultivating long-term relationships built on trust and reliability. In conclusion, the manufacture of high pressure oil hoses is a complex yet fascinating process, marked by a blend of expert knowledge, precise craftsmanship, and unwavering dedication to safety and quality. Factories that prioritize these aspects establish themselves as leaders in the industry, earning them the respected status they hold in the market. For any business in need of high pressure oil hoses, understanding the intricacies of production and the commitment to excellence that these factories embody is essential in making the most informed purchasing decision.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

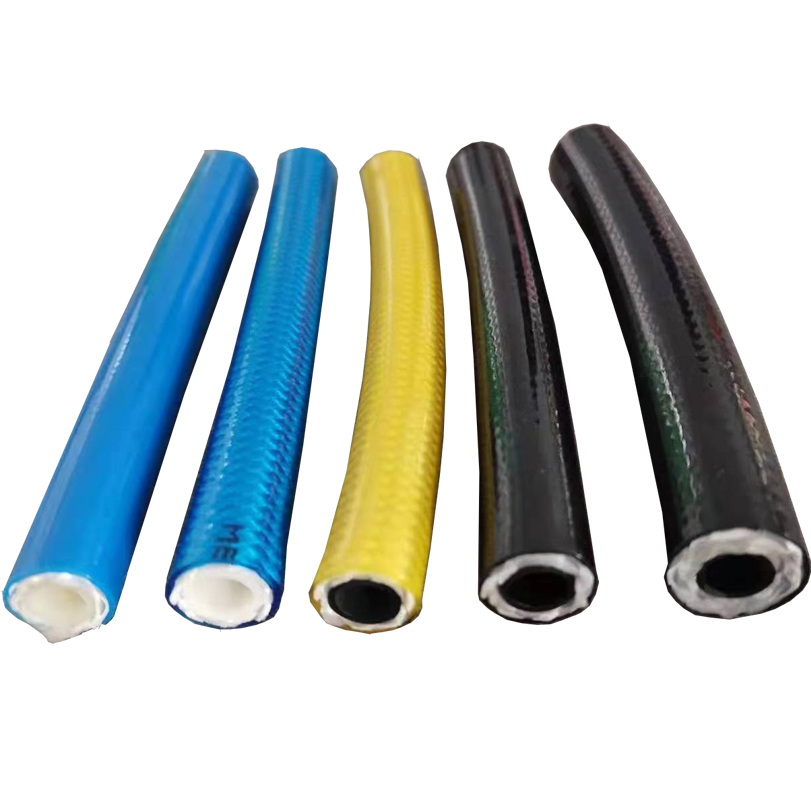

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025