1 月 . 15, 2025 09:36 Back to list

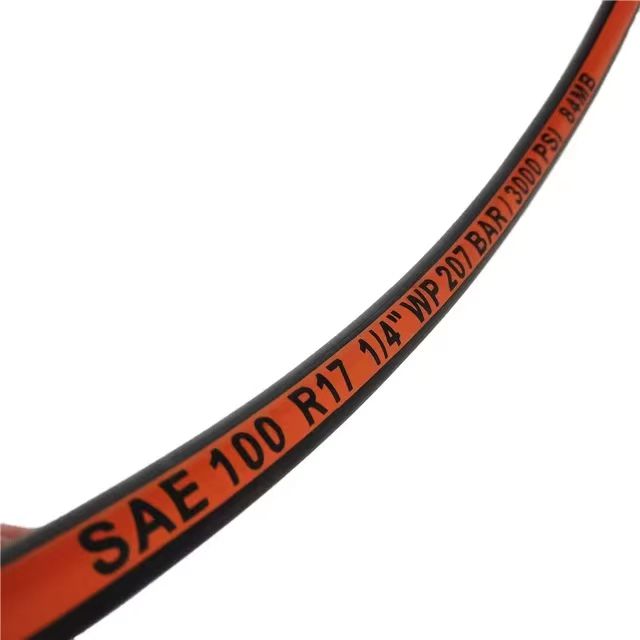

high pressure hydraulic rubber hose

High pressure hydraulic rubber hoses play a critical role in the functionality of hydraulic systems across various industries, ensuring smooth operations and safety. Expertise in selecting and maintaining these hoses can significantly influence the efficiency and longevity of hydraulic equipment.

Routine inspection and maintenance are paramount for preserving hose integrity. High pressure hydraulic rubber hoses should be regularly checked for signs of wear, such as bulges, cracks, or abrasion. Proper handling is equally vital; never bend hoses beyond their designed specifications or subject them to temperatures outside their recommended range. Such practices can significantly extend hose lifespan and effectiveness. In the realm of expertise, knowledge about the nuanced specifications of these hoses is essential. Hydraulic applications demand hoses that can operate safely across various temperature ranges and resist chemical exposure, alongside their primary function of pressure handling. It’s important to consult detailed technical data sheets provided by manufacturers, which outline these specific capabilities, thus aligning product specifications with application needs. Finally, trustworthiness in sources is indispensable when procuring high pressure hydraulic rubber hoses. Opt for certified manufacturers with a track record of quality and customer service excellence. Reliable suppliers will provide not only the product but also support in terms of guidance and expert recommendations, ensuring that the purchases are suited perfectly to their intended environments. In conclusion, high pressure hydraulic rubber hoses are more than just components—they are the backbone of hydraulic systems. Their role in operational safety and efficacy underscores the necessity of expert knowledge in their selection and maintenance. With the right expertise and authoritative guidance, companies can enhance system reliability, ensure safety, and optimize their operations, thereby achieving a sustainable competitive advantage.

Routine inspection and maintenance are paramount for preserving hose integrity. High pressure hydraulic rubber hoses should be regularly checked for signs of wear, such as bulges, cracks, or abrasion. Proper handling is equally vital; never bend hoses beyond their designed specifications or subject them to temperatures outside their recommended range. Such practices can significantly extend hose lifespan and effectiveness. In the realm of expertise, knowledge about the nuanced specifications of these hoses is essential. Hydraulic applications demand hoses that can operate safely across various temperature ranges and resist chemical exposure, alongside their primary function of pressure handling. It’s important to consult detailed technical data sheets provided by manufacturers, which outline these specific capabilities, thus aligning product specifications with application needs. Finally, trustworthiness in sources is indispensable when procuring high pressure hydraulic rubber hoses. Opt for certified manufacturers with a track record of quality and customer service excellence. Reliable suppliers will provide not only the product but also support in terms of guidance and expert recommendations, ensuring that the purchases are suited perfectly to their intended environments. In conclusion, high pressure hydraulic rubber hoses are more than just components—they are the backbone of hydraulic systems. Their role in operational safety and efficacy underscores the necessity of expert knowledge in their selection and maintenance. With the right expertise and authoritative guidance, companies can enhance system reliability, ensure safety, and optimize their operations, thereby achieving a sustainable competitive advantage.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025