2 月 . 13, 2025 02:35 Back to list

high pressure hose factories

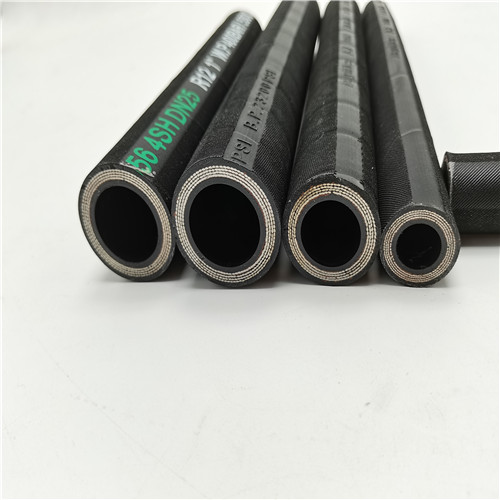

High pressure hoses are indispensable components across numerous industries, playing a pivotal role in maintaining operational efficiency. With a growing reliance on these tubes for various applications, selecting a high-pressure hose factory demands more than just a cursory glance at the price tag. Here’s a deep dive into the world of high-pressure hose manufacturing that highlights essential aspects of expertise, experience, authority, and trustworthiness in the industry.

Moreover, a trustworthy factory typically offers robust customer service. This includes comprehensive warranties and a responsive support team capable of addressing any queries or issues with expedience. For industries relying on seamless operations, having a dependable partner in your hose supplier is invaluable. Emerging technological integrations such as IoT in hose monitoring offer additional value. These smart technologies allow real-time pressure tracking and predictive maintenance, mitigating risks of catastrophic failures. Factories at the forefront of innovation provide these cutting-edge solutions, adding another layer of security and efficiency to operations relying on high-pressure hoses. Factories boasting such comprehensive qualities often have robust distribution networks, ensuring prompt and reliable delivery. Partnerships with well-established logistics providers facilitate a seamless supply chain, which is crucial in maintaining the integrity of operations dependent on timely product replacements or expansions. For industries capitalizing on efficient and safe power transmission through hydraulic or pneumatic systems, the choice of high-pressure hose factory becomes a pivotal decision. By aligning with a manufacturer characterized by extensive experience, certified expertise, industry authority, and proven trustworthiness, businesses ensure sustained productivity and operational excellence. In summary, while cost remains a factor in selecting a factory, it is imperative to consider the broader spectrum of quality indicators which ultimately underpin the safety and efficacy of your operations. By prioritizing these elements, companies not only safeguard their present interests but also fortify their future industrial endeavors.

Moreover, a trustworthy factory typically offers robust customer service. This includes comprehensive warranties and a responsive support team capable of addressing any queries or issues with expedience. For industries relying on seamless operations, having a dependable partner in your hose supplier is invaluable. Emerging technological integrations such as IoT in hose monitoring offer additional value. These smart technologies allow real-time pressure tracking and predictive maintenance, mitigating risks of catastrophic failures. Factories at the forefront of innovation provide these cutting-edge solutions, adding another layer of security and efficiency to operations relying on high-pressure hoses. Factories boasting such comprehensive qualities often have robust distribution networks, ensuring prompt and reliable delivery. Partnerships with well-established logistics providers facilitate a seamless supply chain, which is crucial in maintaining the integrity of operations dependent on timely product replacements or expansions. For industries capitalizing on efficient and safe power transmission through hydraulic or pneumatic systems, the choice of high-pressure hose factory becomes a pivotal decision. By aligning with a manufacturer characterized by extensive experience, certified expertise, industry authority, and proven trustworthiness, businesses ensure sustained productivity and operational excellence. In summary, while cost remains a factor in selecting a factory, it is imperative to consider the broader spectrum of quality indicators which ultimately underpin the safety and efficacy of your operations. By prioritizing these elements, companies not only safeguard their present interests but also fortify their future industrial endeavors.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025