8 月 . 17, 2024 23:47 Back to list

High-Quality OEM Braided LPG Hose for Enhanced Durability and Safety in Gas Applications

The Importance of OEM Braided LPG Hoses in Modern Applications

In recent years, the usage of Liquefied Petroleum Gas (LPG) has surged, powering everything from heating systems to vehicles. As the demand for LPG increases, the need for reliable and efficient delivery systems has become paramount. One essential component of LPG systems is the hose, and OEM (Original Equipment Manufacturer) braided LPG hoses have emerged as a crucial product in this sphere.

What is an OEM Braided LPG Hose?

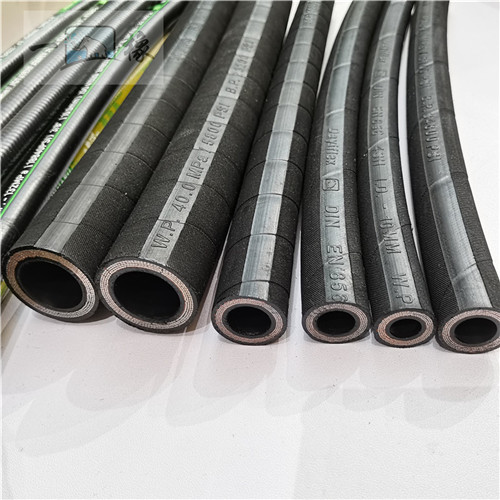

An OEM braided LPG hose is a specialized tube designed to transport liquefied petroleum gas securely and efficiently. The term braided refers to the construction of the hose, which typically comprises a flexible inner tube that carries the LPG, surrounded by one or more layers of braided material. This braided layer commonly utilizes high-strength synthetic fibers or metal wires, which provide added strength, flexibility, and safety. These hoses are manufactured to meet specific standards and specifications set by manufacturers, ensuring compatibility and reliability.

Benefits of OEM Braided LPG Hoses

1. Durability and Reliability The primary benefit of OEM braided LPG hoses is their robust construction. The braided design significantly enhances the hose's resistance to pressure and abrasion, making them ideal for high-pressure applications typically encountered in LPG systems. With the right OEM specifications, these hoses ensure long-term, leak-free operation, reducing the risk of accidents.

2. Safety Safety is a top priority when dealing with LPG, a flammable and potentially hazardous substance. OEM braided hoses are engineered to withstand extreme conditions, reducing the risk of leaks or ruptures that could result in catastrophic failures. Leading manufacturers invest in rigorous testing and quality control to ensure that their hoses meet safety standards.

oem braided lpg hose

3. Flexibility and Maneuverability The braided construction contributes to the hose's flexibility, enabling it to bend and maneuver in tight spaces without compromising safety or performance. This characteristic is particularly important in installations where the hose must navigate around obstacles or fit into confined areas.

4. Temperature Resistance LPG hoses must withstand varying temperatures, from scorching heat to freezing cold. OEM braided LPG hoses are designed to maintain their integrity under extreme thermal conditions, ensuring consistent performance across different environments. This adaptability is essential for applications ranging from domestic use to industrial settings.

5. Compatibility Using OEM products guarantees that the hose fits seamlessly within existing systems. This compatibility reduces the risk of malfunction and increases efficiency. OEM braided hoses are tailored to adhere to specific standards, which helps in maintaining the overall integrity of LPG systems.

Applications of OEM Braided LPG Hoses

The versatility of OEM braided LPG hoses makes them ideal for a wide range of applications. They are commonly used in residential heating systems, outdoor grills, commercial kitchens, and even in autogas systems for LPG-fueled vehicles. Additionally, industries such as agriculture and manufacturing utilize these hoses for various applications, underscoring their importance in different sectors.

Conclusion

As the demand for LPG continues to rise, the importance of reliable delivery systems cannot be overstated. OEM braided LPG hoses stand out due to their durability, safety, flexibility, and compatibility with existing systems. Investing in quality OEM products not only ensures compliance with safety regulations but also contributes to the efficient and safe use of liquefied petroleum gas. For anyone dealing with LPG, prioritizing OEM braided hoses is essential for sustaining high standards in safety and performance. In a world where safety and efficiency are paramount, these hoses are truly an indispensable component of LPG systems.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025