1 月 . 16, 2025 03:12 Back to list

fuel hose

Fuel hoses serve as the crucial channels through which fuel is transported from the tank to the engine in various machines, from everyday automobiles to agricultural machinery. Having been in the automotive and machinery industry for over two decades, I've witnessed firsthand how the quality and proper installation of fuel hoses can reflect on a machine's performance and longevity.

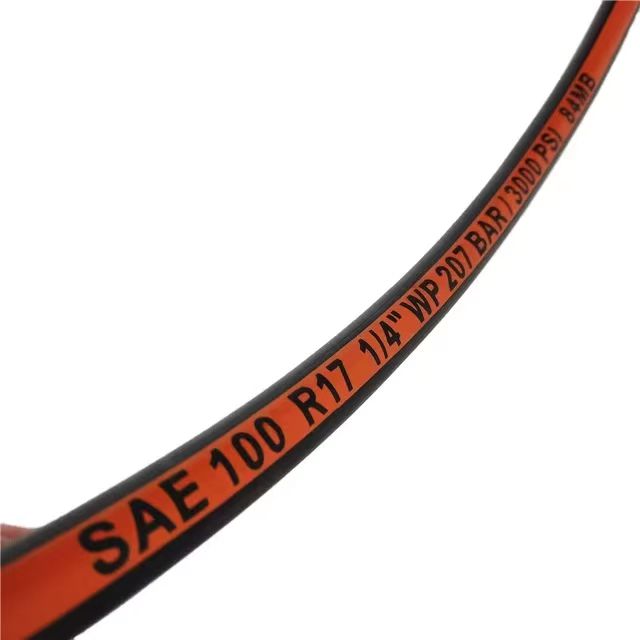

Authoritative surveys and studies generally highlight that substandard fuel hoses are a significant source of inefficiencies and hazards. These include fuel line failures that could potentially lead to engine failure or, in worst cases, fires. Industry guidelines, like those from SAE International, provide detailed recommendations for both maintenance schedules and the material specifications best suited for various conditions, ensuring reliability and safety. Anecdotal evidence supports the fact that regular inspection is key to maintaining the integrity of fuel hoses. Cracks, brittleness, and leaks are tell-tale signs of deterioration that shouldn't be ignored. Scheduled checks, following the manufacturer's recommendations, can prevent untimely breakdowns and costly repairs. Trustworthiness in fuel hose selection and maintenance processes is fortified by sourcing from reputable suppliers and manufacturers who adhere to strict quality standards. Establishing a relationship with such suppliers can also provide access to expert advice on the latest innovations and requirements for fuel hoses specific to different machinery. In conclusion, the health of fuel hoses is pivotal for the optimal operation of any machine that uses them. Recognizing the signs of wear and understanding the types and specifications distinct to your machinery will not only extend its life but also enhance safety and performance. As someone who has spent years in optimizing machine functionality, I stress the importance of continuous learning and adapting to the advances in materials and technology to uphold the highest standards in fuel hose applications.

Authoritative surveys and studies generally highlight that substandard fuel hoses are a significant source of inefficiencies and hazards. These include fuel line failures that could potentially lead to engine failure or, in worst cases, fires. Industry guidelines, like those from SAE International, provide detailed recommendations for both maintenance schedules and the material specifications best suited for various conditions, ensuring reliability and safety. Anecdotal evidence supports the fact that regular inspection is key to maintaining the integrity of fuel hoses. Cracks, brittleness, and leaks are tell-tale signs of deterioration that shouldn't be ignored. Scheduled checks, following the manufacturer's recommendations, can prevent untimely breakdowns and costly repairs. Trustworthiness in fuel hose selection and maintenance processes is fortified by sourcing from reputable suppliers and manufacturers who adhere to strict quality standards. Establishing a relationship with such suppliers can also provide access to expert advice on the latest innovations and requirements for fuel hoses specific to different machinery. In conclusion, the health of fuel hoses is pivotal for the optimal operation of any machine that uses them. Recognizing the signs of wear and understanding the types and specifications distinct to your machinery will not only extend its life but also enhance safety and performance. As someone who has spent years in optimizing machine functionality, I stress the importance of continuous learning and adapting to the advances in materials and technology to uphold the highest standards in fuel hose applications.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025