3 月 . 07, 2025 02:10 Back to list

four wire spiral high pressure hydraulic hose manufacturers

In the specialized field of hydraulic systems, choosing the right components can significantly influence performance and reliability. One of the most critical components is the hydraulic hose. While selecting, especially for high-pressure environments, a four-wire spiral high-pressure hydraulic hose stands out for its robustness and efficiency.

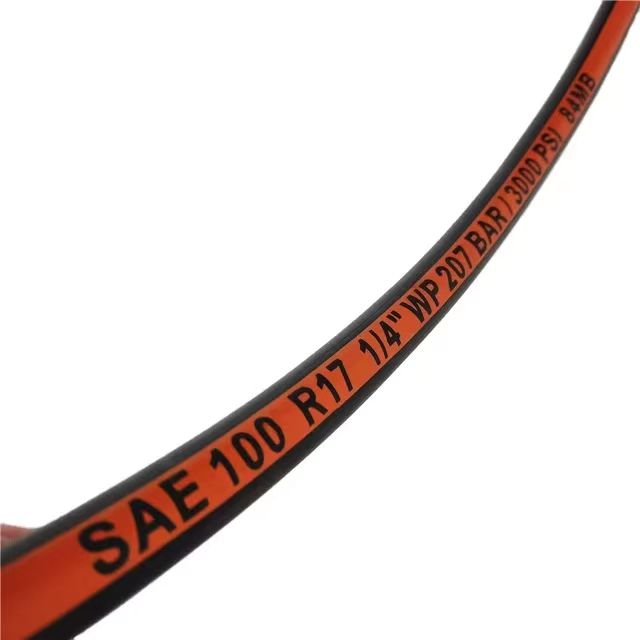

Expertise in this field involves more than just materials—it demands a profound understanding of the hydraulic systems themselves. Manufacturers must tailor each hose to meet specific certifications and standards, like SAE (Society of Automotive Engineers) or ISO (International Standards Organization) guidelines, which govern aspects such as construction, size, and pressure ratings. These standards ensure that every hose can consistently deliver unparalleled performance under stringent conditions. One authoritative approach to selecting a hydraulic hose manufacturer involves examining their industry certifications and their reputation in delivering customized solutions. Top-tier providers offer hoses that not only meet standard specifications but also provide additional testing and enhancements upon request. These enhancements might include temperature resilience, flexibility under extreme conditions, and resistance to particular chemicals or oils. Trustworthiness in a manufacturer becomes evident through their transparency about production processes, material sources, and performance guarantees. Many leading manufacturers provide comprehensive testing results and batch tracking, offering a higher degree of confidence for OEMs (Original Equipment Manufacturers) and their suppliers. The best companies also invest in R&D to continuously improve hose technologies, responding to the ever-evolving demands of the hydraulic industry. When navigating the market for a suitable manufacturer, potential clients should seek insights from testimonials and case studies readily available from industry peers. A reliable manufacturer will be those with a proven track record of delivering solutions that exceed industry expectations—not just meeting them. In conclusion, a four-wire spiral high-pressure hydraulic hose offers unparalleled strength and durability for critical applications. Manufacturers in this sector distinguish themselves through exceptional engineering expertise, strong adherence to international standards, and a commitment to continuous innovation. By choosing a trusted partner, clients can enhance their hydraulic systems' efficiency and longevity, reinforcing the overall performance integrity across their operations.

Expertise in this field involves more than just materials—it demands a profound understanding of the hydraulic systems themselves. Manufacturers must tailor each hose to meet specific certifications and standards, like SAE (Society of Automotive Engineers) or ISO (International Standards Organization) guidelines, which govern aspects such as construction, size, and pressure ratings. These standards ensure that every hose can consistently deliver unparalleled performance under stringent conditions. One authoritative approach to selecting a hydraulic hose manufacturer involves examining their industry certifications and their reputation in delivering customized solutions. Top-tier providers offer hoses that not only meet standard specifications but also provide additional testing and enhancements upon request. These enhancements might include temperature resilience, flexibility under extreme conditions, and resistance to particular chemicals or oils. Trustworthiness in a manufacturer becomes evident through their transparency about production processes, material sources, and performance guarantees. Many leading manufacturers provide comprehensive testing results and batch tracking, offering a higher degree of confidence for OEMs (Original Equipment Manufacturers) and their suppliers. The best companies also invest in R&D to continuously improve hose technologies, responding to the ever-evolving demands of the hydraulic industry. When navigating the market for a suitable manufacturer, potential clients should seek insights from testimonials and case studies readily available from industry peers. A reliable manufacturer will be those with a proven track record of delivering solutions that exceed industry expectations—not just meeting them. In conclusion, a four-wire spiral high-pressure hydraulic hose offers unparalleled strength and durability for critical applications. Manufacturers in this sector distinguish themselves through exceptional engineering expertise, strong adherence to international standards, and a commitment to continuous innovation. By choosing a trusted partner, clients can enhance their hydraulic systems' efficiency and longevity, reinforcing the overall performance integrity across their operations.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025