1 月 . 17, 2025 06:06 Back to list

Wire Braided LPG&CNG Gas Hose

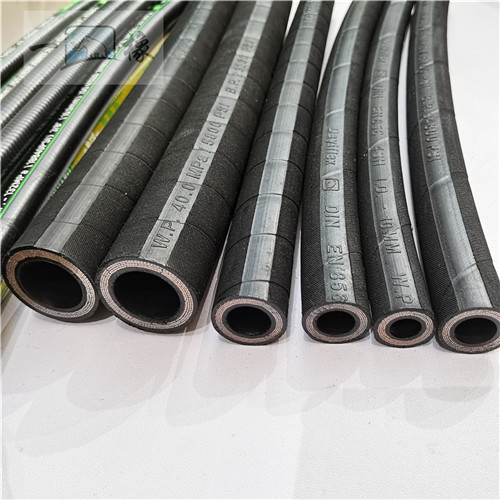

Navigating the myriad options in the hydraulic hose market can be daunting, especially for those tasked with choosing reliable components for critical applications. Among the seasoned products in this field, the four-wire spiral high-pressure hydraulic hose stands out, known for its robust construction and superior performance under high-pressure conditions. This article explores the intricacies of this hydraulic hose type and underscores its unmatched benefits.

One salient benefit of the four-wire spiral high-pressure hydraulic hose is its remarkable flexibility, given its robust construction. Engineers appreciate the ease of routing this hose through complex machinery frameworks without compromising performance. The hose's flexibility also aids in reducing installation time, facilitating smoother setup processes in both new and retrofit applications. Manufacturers of these hydraulic hoses often incorporate innovative materials and construction techniques, investing in research and development to push the limits of what these hoses can achieve. This focus on innovation not only ensures adherence to current industry standards but often sets new benchmarks for competitors, reinforcing the manufacturer’s status as industry leaders. Real-world applications demonstrate the effectiveness of these hoses in reducing system noise and vibration. Operators in the field report smoother operation, thanks to the hose's ability to absorb and dampen the dynamic forces typical in hydraulic systems. This feature particularly enhances the end-user experience in environments where noise pollution is a concern. The commitment to sustainability is another notable aspect of these products. Leading manufacturers employ eco-friendly processes and materials, aiming to minimize environmental impact without compromising hose quality. This focus on sustainability merges industry expertise with environmental stewardship, meeting expectations of modern consumers who value responsible manufacturing practices. In conclusion, the four-wire spiral high-pressure hydraulic hose is a testament to the blend of engineering prowess and practical application. Its unparalleled strength, flexible adaptability, and high performance in demanding pressures make it a preferred choice among industry professionals. The reputability of these hoses underscores a commitment to quality and reliability, ensuring that they remain a staple in hydraulic systems across various sectors. When it comes to optimizing high-pressure systems, this hydraulic hose type offers unmatched experience, expertise, and trusted authority in its field.

One salient benefit of the four-wire spiral high-pressure hydraulic hose is its remarkable flexibility, given its robust construction. Engineers appreciate the ease of routing this hose through complex machinery frameworks without compromising performance. The hose's flexibility also aids in reducing installation time, facilitating smoother setup processes in both new and retrofit applications. Manufacturers of these hydraulic hoses often incorporate innovative materials and construction techniques, investing in research and development to push the limits of what these hoses can achieve. This focus on innovation not only ensures adherence to current industry standards but often sets new benchmarks for competitors, reinforcing the manufacturer’s status as industry leaders. Real-world applications demonstrate the effectiveness of these hoses in reducing system noise and vibration. Operators in the field report smoother operation, thanks to the hose's ability to absorb and dampen the dynamic forces typical in hydraulic systems. This feature particularly enhances the end-user experience in environments where noise pollution is a concern. The commitment to sustainability is another notable aspect of these products. Leading manufacturers employ eco-friendly processes and materials, aiming to minimize environmental impact without compromising hose quality. This focus on sustainability merges industry expertise with environmental stewardship, meeting expectations of modern consumers who value responsible manufacturing practices. In conclusion, the four-wire spiral high-pressure hydraulic hose is a testament to the blend of engineering prowess and practical application. Its unparalleled strength, flexible adaptability, and high performance in demanding pressures make it a preferred choice among industry professionals. The reputability of these hoses underscores a commitment to quality and reliability, ensuring that they remain a staple in hydraulic systems across various sectors. When it comes to optimizing high-pressure systems, this hydraulic hose type offers unmatched experience, expertise, and trusted authority in its field.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025