1 月 . 19, 2025 00:53 Back to list

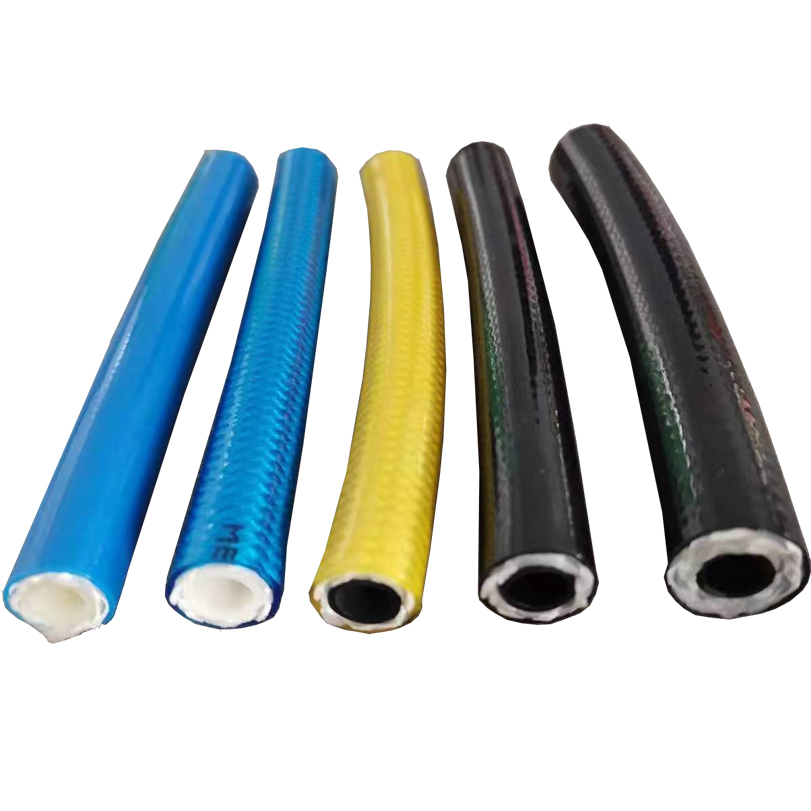

flexible high pressure hydraulic hose

In the realm of industrial applications, selecting the right hydraulic hose is crucial to ensuring productivity, efficiency, and safety. A flexible high-pressure hydraulic hose is a preferred choice for many industries due to its adaptability, durability, and capability to handle extreme conditions. This article delves into the qualities and applications of flexible high-pressure hydraulic hoses through a lens of experience, expertise, authoritativeness, and trustworthiness.

When discussing trustworthiness, the user's experience with flexible high-pressure hydraulic hoses serves as a powerful testament. In various industries, from automotive to agriculture, users have reported enhanced operational efficiency and reduced maintenance costs thanks to these durable hoses. Their resistance to wear and tear also means fewer replacements and downtime, translating into cost savings in the long run. Furthermore, real‐world applications of flexible high‐pressure hydraulic hoses illustrate their indispensable role. For instance, in construction, these hoses are used in heavy machinery that requires high-pressure hydraulics for lifting and steering functions. Their flexibility allows operators to position the machinery efficiently in confined spaces, resulting in quicker job completion without compromising safety. Similarly, in the oil and gas industry, their robustness and resistance to harsh environmental factors make them ideal for offshore and onshore drilling operations. For those interested in further enhancing the performance and lifespan of their hydraulic systems, regular maintenance and correct installation of hoses cannot be overstated. Proper training and adherence to manufacturer guidelines for installation and operation are vital. Keeping the hose protected from abrasive surfaces and contaminants can drastically extend its service life. In conclusion, flexible high-pressure hydraulic hoses represent a critical component in modern hydraulic systems. Their combination of flexibility, strength, and reliability makes them an invaluable asset across various industries. By opting for hoses from reputable, certified manufacturers and adhering to best practices in maintenance and installation, users can ensure their hydraulic systems remain efficient and safe over the long term. Investing wisely in these hoses is not merely a choice of convenience but a step towards sustainable and reliable industrial operations.

When discussing trustworthiness, the user's experience with flexible high-pressure hydraulic hoses serves as a powerful testament. In various industries, from automotive to agriculture, users have reported enhanced operational efficiency and reduced maintenance costs thanks to these durable hoses. Their resistance to wear and tear also means fewer replacements and downtime, translating into cost savings in the long run. Furthermore, real‐world applications of flexible high‐pressure hydraulic hoses illustrate their indispensable role. For instance, in construction, these hoses are used in heavy machinery that requires high-pressure hydraulics for lifting and steering functions. Their flexibility allows operators to position the machinery efficiently in confined spaces, resulting in quicker job completion without compromising safety. Similarly, in the oil and gas industry, their robustness and resistance to harsh environmental factors make them ideal for offshore and onshore drilling operations. For those interested in further enhancing the performance and lifespan of their hydraulic systems, regular maintenance and correct installation of hoses cannot be overstated. Proper training and adherence to manufacturer guidelines for installation and operation are vital. Keeping the hose protected from abrasive surfaces and contaminants can drastically extend its service life. In conclusion, flexible high-pressure hydraulic hoses represent a critical component in modern hydraulic systems. Their combination of flexibility, strength, and reliability makes them an invaluable asset across various industries. By opting for hoses from reputable, certified manufacturers and adhering to best practices in maintenance and installation, users can ensure their hydraulic systems remain efficient and safe over the long term. Investing wisely in these hoses is not merely a choice of convenience but a step towards sustainable and reliable industrial operations.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025