8 月 . 17, 2024 23:47 Back to list

Explore Top Manufacturers of 16mm Hydraulic Hoses and Their Quality Production Techniques

The Development and Importance of 16mm Hydraulic Hose Factories

In the realm of industrial manufacturing, hydraulic hoses play a crucial role in transmitting fluid power. Among the various sizes available, 16mm hydraulic hoses have garnered significant attention due to their versatile applications across multiple industries, such as construction, agriculture, and manufacturing. As a result, the establishment and growth of 16mm hydraulic hose factories have become essential to meet the increasing demand for quality hydraulic products.

Hydraulic systems rely on the efficient transfer of fluids under pressure, and the components used, especially hoses, need to withstand various environmental and operational stresses. The 16mm hydraulic hose is particularly favored for its balance between flexibility and strength. Factories producing these hoses focus on employing high-quality materials, advanced manufacturing techniques, and strict quality control measures to ensure that the hoses can safely handle high pressures and resist wear and tear over time.

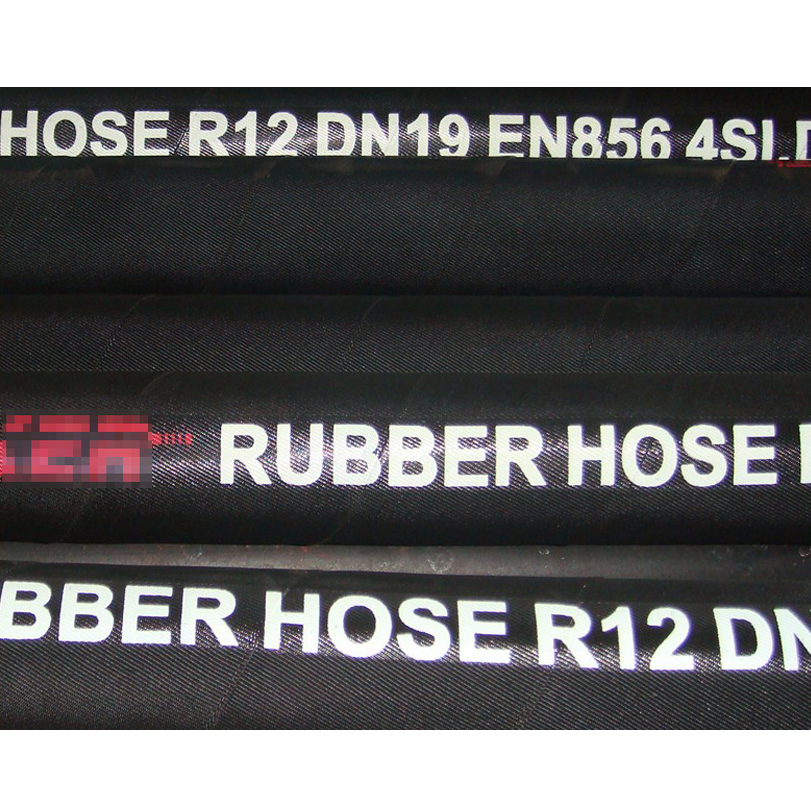

The manufacturing process of 16mm hydraulic hoses involves several stages, starting with the selection of raw materials. Typically, manufacturers use a combination of synthetic rubber, textile reinforcements, and steel wire. The rubber provides resilience and flexibility, while the textile and steel reinforcements enhance the hose's durability and pressure tolerance. Factories often utilize state-of-the-art machinery such as extrusion and molding equipment to produce hoses that meet international standards.

One of the pivotal aspects of establishing a successful 16mm hydraulic hose factory is adherence to rigorous quality control processes. These factories implement testing methodologies such as burst testing, impulse testing, and abrasion testing to ensure that each product meets the required specifications. Hochul tests, for example, assess how well the hose can withstand repetitive flexing and bending, which mimics real-world usage conditions. Furthermore, certifications from organizations such as ISO and SAE enhance the credibility of these factories, assuring customers of the reliability of their products.

16mm hydraulic hose factories

In addition to quality, customization has become a key selling point for many 16mm hydraulic hose manufacturers. Different industries have unique requirements, which may involve specific lengths, fittings, or temperature ratings. Factories that can tailor their offerings to meet these demands often gain a competitive edge in the market. By investing in advanced technology and skilled labor, manufacturers are able to produce custom hoses efficiently while maintaining high standards.

The global market for hydraulic hoses, including the 16mm variety, has seen considerable growth, driven by several factors such as industrial advancements and increased infrastructure projects. In particular, countries with booming economies are witnessing an uptick in construction and agricultural activities, leading to a higher demand for reliable hydraulic systems. Consequently, the proliferation of 16mm hydraulic hose factories is a direct response to this rising demand, as they strive to deliver high-quality products that enhance operational efficiency.

Moreover, the advent of e-commerce has also transformed the way hydraulic hoses are sold. Customers can now easily compare products and prices from different manufacturers, facilitating informed purchasing decisions. This competitive landscape encourages factories to innovate continuously and improve their offerings, fostering a culture of quality and customer service.

In conclusion, the rise of 16mm hydraulic hose factories underscores the growing importance of hydraulic components in various industries. With a focus on quality assurance, customization, and customer service, these factories are well-positioned to meet the demands of modern industrial applications. As the need for efficient fluid power transmission continues to expand globally, the role of these manufacturing facilities will remain critical in supporting industry growth and innovation.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025