8 月 . 17, 2024 23:51 Back to list

Custom OEM Braided Hydraulic Hose Manufacturer for High-Quality Fluid Transfer Solutions and Applications

The Rise of OEM Braided Hydraulic Hose Manufacturers Ensuring Quality and Performance

In the world of industrial equipment and machinery, the significance of reliable hydraulic systems cannot be overstated. At the core of these systems lie hydraulic hoses, which facilitate the transmission of fluid power while stabilizing pressure levels. Among the various types of hydraulic hoses, OEM braided hydraulic hoses have emerged as a preferred choice for many manufacturers across different industries. This article explores the evolution and benefits of choosing OEM (Original Equipment Manufacturer) braided hydraulic hose manufacturers for reliable and high-performance solutions.

Understanding OEM Braided Hydraulic Hoses

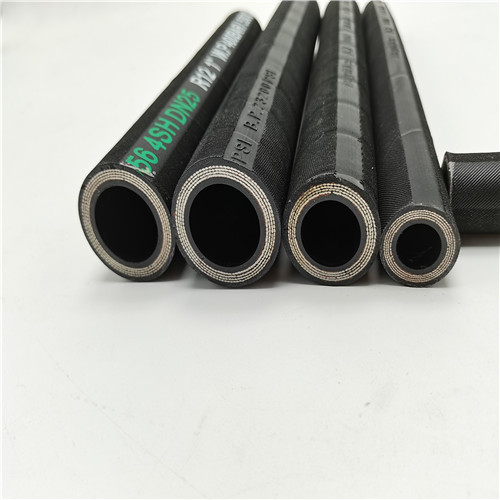

OEM braided hydraulic hoses are engineered to meet or exceed the specifications and performance standards set by original equipment manufacturers. These hoses are typically made from high-quality materials, including synthetic rubber, which is reinforced with layers of braided steel wire. This design enhances their strength and durability, allowing them to withstand high pressure and harsh environmental conditions commonly encountered in industrial applications.

The braided structure of these hoses not only provides exceptional strength but also flexibility, making them easier to install and maneuver in tight spaces. Furthermore, the outer layer of the hose often features protective coatings or coverings that guard against abrasion, UV exposure, and chemical attacks, thus extending the lifespan of the hose.

The Advantages of Partnering with OEM Manufacturers

1. Quality Assurance OEM braided hydraulic hose manufacturers adhere to strict quality control processes, ensuring that every hose produced meets specific performance standards and regulatory requirements. This commitment to quality translates to reduced downtime and maintenance costs for businesses that depend on reliable hydraulic systems.

2. Customization One of the primary advantages of working with OEM manufacturers is the ability to obtain customized solutions. OEM manufacturers can tailor braided hydraulic hoses to meet the unique requirements of their clients, including different lengths, diameters, and pressure ratings. This level of customization ensures that businesses receive products that perfectly fit their equipment and operational needs.

oem braided hydraulic hose manufacturer

3. Technical Support and Expertise OEM manufacturers often have extensive experience and expertise in the hydraulic industry. They can provide valuable insights into the best practices for hose selection, installation, and maintenance, ultimately helping customers optimize their hydraulic systems' performance.

4. Compliance and Certification Hydraulic systems must comply with various industry standards and regulations. OEM braided hydraulic hose manufacturers provide hoses that are certified and compliant, ensuring that businesses operate safely and within legal parameters.

5. Competitive Pricing While some may assume that OEM products come with a higher price tag, the investment often pays off in the long run. By choosing OEM braided hydraulic hoses, businesses can minimize the risk of hose failure, which can lead to catastrophic equipment damage and costly repairs.

The Future of OEM Braided Hydraulic Hose Manufacturing

As industries continue to evolve, the demand for high-quality hydraulic systems will persist. OEM braided hydraulic hose manufacturers are likely to invest in advanced technologies and materials to improve hose performance further. Innovations such as smart sensors integrated into hoses, which can monitor pressure levels and detect leaks in real-time, are already on the horizon.

Moreover, as sustainability becomes a pressing issue, manufacturers are exploring eco-friendly materials and production processes. This commitment to sustainable practices not only helps protect the environment but also meets the growing consumer demand for responsible manufacturing.

In conclusion, the role of OEM braided hydraulic hose manufacturers is paramount in ensuring the reliability and efficiency of hydraulic systems across various industries. By prioritizing quality, customization, and compliance, these manufacturers are setting the stage for innovation and excellence in hydraulic technology. As industries advance, the partnership between equipment manufacturers and OEM hose suppliers will remain crucial in driving performance and sustainability forward.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025