8 月 . 17, 2024 23:54 Back to list

Custom Hydraulic Hoses for OEM Applications Durable Solutions for Your Fluid Transfer Needs

The Importance of OEM Hydraulic Hoses in Industrial Applications

In various industrial applications, hydraulic systems play a critical role in ensuring efficient operation and functionality. At the heart of these systems lies a crucial component the hydraulic hose. Original Equipment Manufacturer (OEM) hydraulic hoses are specifically designed to meet the standards and specifications required by manufacturers for optimum performance and safety. This article explores the significance of OEM hydraulic hoses, their advantages, and factors to consider when selecting these components.

Understanding OEM Hydraulic Hoses

OEM hydraulic hoses are custom-made components that adhere to the exact specifications provided by the manufacturer of the hydraulic system. They are built to match the original equipment’s design requirements, ensuring compatibility and optimal performance. Unlike generic hydraulic hoses, which may vary in material, dimension, and quality, OEM hoses guarantee a precise fit and function.

Advantages of OEM Hydraulic Hoses

1. Quality Assurance One of the primary benefits of OEM hydraulic hoses is the assurance of quality. These hoses are manufactured using high-grade materials that can withstand intense pressure and extreme environmental conditions. This quality translates to durability, reducing the need for frequent replacements.

2. Enhanced Performance OEM hoses are specifically engineered for use in particular hydraulic systems. This specialized design leads to better efficiency in fluid power transmission, translating to improved performance of the equipment in which they are installed.

3. Safety and Compliance Safety is paramount in industrial operations, and OEM hydraulic hoses help to mitigate risks associated with hydraulic failures. They comply with industry standards and regulations, ensuring that operations remain safe for both workers and equipment.

4. Warranty Protection When utilizing OEM components, businesses often have the added benefit of warranty coverage. Using non-OEM parts can sometimes void a manufacturer's warranty, thereby increasing future repair costs.

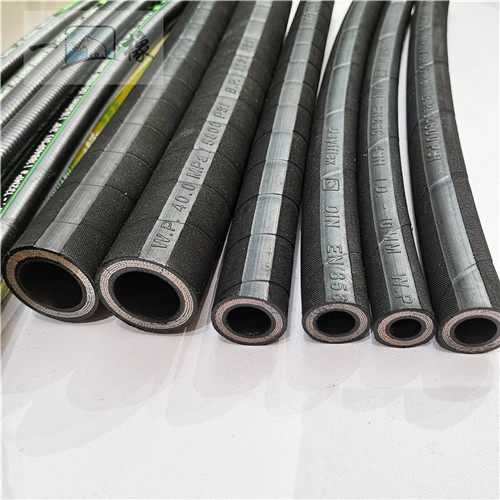

oem hydraulic hose

Selecting the Right OEM Hydraulic Hose

When choosing an OEM hydraulic hose, several factors must be considered to ensure optimal performance.

1. Compatibility The first step is to verify that the hose matches the specifications of the hydraulic system. This includes checking the hose diameter, length, and connection type.

2. Material Quality Different applications may require hoses made of specific materials, such as rubber or thermoplastic. It is important to choose hoses that can endure the temperature and pressure conditions of the application.

3. Operating Conditions Evaluate the environmental conditions the hose will be exposed to, such as temperature fluctuations, chemical exposure, and abrasion risks. Selecting hoses designed for specific operating conditions enhances longevity and minimizes maintenance costs.

4. Manufacturer Reputation Always source OEM hoses from reputable manufacturers known for their commitment to quality and reliability. Research their warranty policies, customer reviews, and after-sales support to ensure a satisfactory purchasing experience.

Conclusion

OEM hydraulic hoses are indispensable in maintaining the efficiency and safety of industrial hydraulic systems. Their unique advantages—quality assurance, enhanced performance, compliance with safety standards, and potential for warranty coverage—make them the preferred choice for businesses aiming for operational excellence. By understanding the critical factors involved in selecting the right hose, industries can ensure seamless operations and reduced downtime, ultimately leading to increased productivity and profitability in their operations. Investing in OEM hydraulic hoses is not just a wise decision; it is a commitment to achieving the highest standards of safety and efficiency in industrial applications.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025