12 月 . 04, 2024 09:27 Back to list

china water suction and discharge rubber hose factories

China's Water Suction and Discharge Rubber Hose Factories An Overview

In the realm of industrial applications, water suction and discharge rubber hoses play critical roles, especially in sectors like agriculture, construction, and municipal services. China, as one of the leading manufacturers of rubber products, has established a substantial presence in the production of these hoses. This article explores the landscape of water suction and discharge rubber hose factories in China, emphasizing their significance, manufacturing processes, and contributions to various industries.

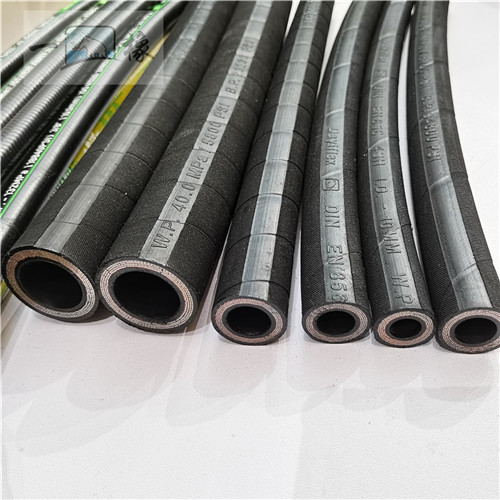

Water suction and discharge hoses are essential for transporting water and other fluids safely and efficiently. These hoses are designed to withstand high pressure and are made from various materials, primarily rubber due to its flexibility, durability, and resistance to abrasion. In China, numerous factories specialize in the production of these hoses, tapping into the country’s rich resources of rubber and advanced manufacturing techniques.

Manufacturing Process

The manufacturing process of water suction and discharge rubber hoses in China involves several critical steps. Initially, raw materials such as natural rubber, synthetic rubber (like EPDM or SBR), fabric reinforcements, and other additives are sourced. The selection of these materials is crucial; they need to meet specific industry standards and performance criteria, such as pressure rating and flexibility.

The manufacturing process typically begins with the mixing of rubber compounds. This process is carried out in large mixers where the raw materials are blended thoroughly to achieve the desired properties. Following this, the mixed rubber is extruded into the desired hose shape. This stage is integral to ensuring uniformity and consistency in the product.

After extrusion, the hoses undergo a series of treatments, which may include the application of a textile or wire reinforcement to enhance strength and resistance to wear and tear. The hoses are then cured through a process known as vulcanization, wherein heat is applied to set the rubber and improve its elasticity and durability.

china water suction and discharge rubber hose factories

Quality Control and Standards

Chinese factories adhere to stringent quality control measures throughout the manufacturing process. Certifications such as ISO 9001 ensure that the factories maintain a standardized approach to quality management. Additionally, products are routinely tested for aspects like pressure tolerance, temperature resistance, and chemical compatibility. This commitment to quality not only meets domestic demand but also positions Chinese manufacturers favorably in international markets.

Market Demand and Applications

The demand for water suction and discharge rubber hoses continues to grow, propelled by various sectors. In agriculture, these hoses are indispensable for irrigation systems, allowing farmers to manage water resources efficiently. In construction, they facilitate water transfer for various applications, including concrete mixing and excavation. Moreover, municipal services utilize these hoses for drainage and sewage management, underscoring their importance in urban infrastructure.

Conclusion

China's water suction and discharge rubber hose factories epitomize the country’s prowess in rubber manufacturing and industrial production. With a robust manufacturing infrastructure, adherence to quality standards, and an ever-growing market demand, these factories are well-positioned to maintain and expand their roles in both domestic and global markets. As industries evolve and the need for efficient fluid transfer solutions increases, China's factories are set to remain at the forefront of this essential segment, ensuring the delivery of high-quality, reliable rubber hoses for a wide array of applications. The synergy of advanced manufacturing practices and rigorous quality control underscores the importance of these factories in the global marketplace, making them pivotal players in the industrial landscape.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025