2 月 . 04, 2025 06:17 Back to list

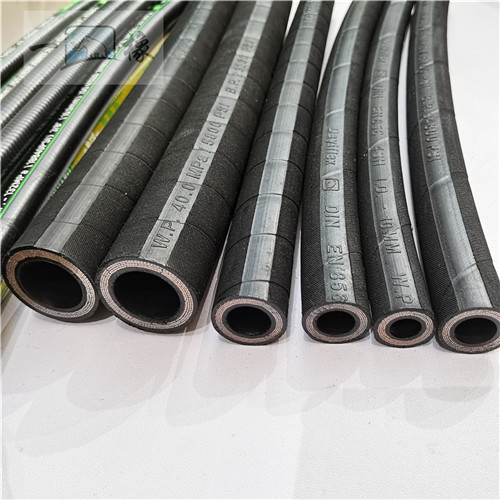

DIN EN 857 1SC Black Smooth Cover Hydraulic Hose

The world of hydraulic hoses is intricate and multifaceted, with the SAE100R16 standard representing a pinnacle of engineering and reliability in fluid power applications. Crafted with utmost precision, hoses conforming to this standard are revered for their high-pressure capacity and exceptional flexibility, making them indispensable in industries such as agriculture, construction, and manufacturing.

The adaptability of the SAE100R16 hose cannot be overstated. Often used in high-pressure fluid transfer, these hoses are integral components in applications ranging from earthmoving equipment to injection molding machines. Their ability to perform under duress ensures that industries can maintain continuous operations without the risk of unexpected hose failure. From an economic standpoint, investing in SAE100R16 hoses can result in reduced operational costs over time. While the initial investment might be higher than conventional hoses, the enhanced durability and reduced maintenance requirements translate into significant savings. This makes it an economically sound choice for businesses aiming for sustainable operational efficiency. Experts in mechanical engineering and hydraulic system design often emphasize the importance of selecting the right hose to avoid costly system breakdowns. The SAE100R16's compatibility with a wide range of fittings and connectors also simplifies the installation process, allowing for a seamless integration into existing systems. Moreover, continuous advancements in material science are influencing the SAE100R16 hoses' evolution, with innovations that further enhance their temperature resistance and pressure handling capabilities. As industries evolve and demand even greater efficiency, these hoses are set to adapt, maintaining their position as an industry benchmark. In conclusion, for stakeholders invested in the seamless operation of hydraulic systems, choosing the right hose is crucial. The SAE100R16 hose, with its exemplary pressure capacity, flexibility, and compliance with stringent safety standards, represents an unparalleled asset. Its contribution to enhancing operational efficiency, minimizing downtime, and ensuring safety reinforces its status as a critical component in modern industrial applications. As businesses strive to future-proof their operations, embracing such proven and trusted solutions is a decisive step towards long-term success and reliability.

The adaptability of the SAE100R16 hose cannot be overstated. Often used in high-pressure fluid transfer, these hoses are integral components in applications ranging from earthmoving equipment to injection molding machines. Their ability to perform under duress ensures that industries can maintain continuous operations without the risk of unexpected hose failure. From an economic standpoint, investing in SAE100R16 hoses can result in reduced operational costs over time. While the initial investment might be higher than conventional hoses, the enhanced durability and reduced maintenance requirements translate into significant savings. This makes it an economically sound choice for businesses aiming for sustainable operational efficiency. Experts in mechanical engineering and hydraulic system design often emphasize the importance of selecting the right hose to avoid costly system breakdowns. The SAE100R16's compatibility with a wide range of fittings and connectors also simplifies the installation process, allowing for a seamless integration into existing systems. Moreover, continuous advancements in material science are influencing the SAE100R16 hoses' evolution, with innovations that further enhance their temperature resistance and pressure handling capabilities. As industries evolve and demand even greater efficiency, these hoses are set to adapt, maintaining their position as an industry benchmark. In conclusion, for stakeholders invested in the seamless operation of hydraulic systems, choosing the right hose is crucial. The SAE100R16 hose, with its exemplary pressure capacity, flexibility, and compliance with stringent safety standards, represents an unparalleled asset. Its contribution to enhancing operational efficiency, minimizing downtime, and ensuring safety reinforces its status as a critical component in modern industrial applications. As businesses strive to future-proof their operations, embracing such proven and trusted solutions is a decisive step towards long-term success and reliability.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025