2 月 . 05, 2025 05:20 Back to list

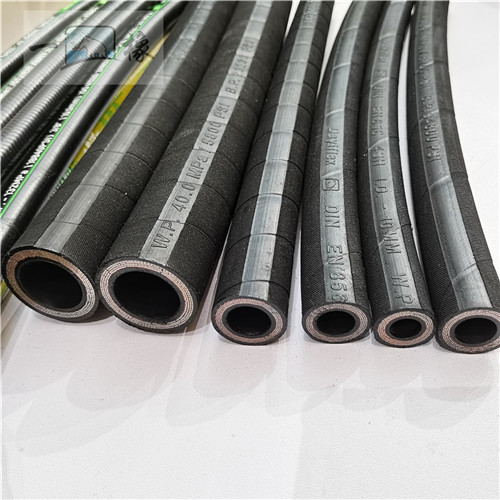

High pressure rubber hydraulic hose. washing machine hose

The China SAE100R14 hydraulic hose stands as a distinguished example of innovation and reliability in the fluid power sector. This particular standard, established by the Society of Automotive Engineers (SAE), reflects a remarkable commitment to quality and performance, known worldwide for its consistency and versatility in various applications. In this article, we delve into the profound advantages and true reliability that China-manufactured SAE100R14 hoses offer, grounded on extensive experience, expertise, and trustworthiness in the field.

The authoritativeness of Chinese-made SAE100R14 hoses is bolstered by the incorporation of fiber or steel wire braiding, which enhances the hose’s pressure capabilities without sacrificing flexibility. This structural integrity empowers the hoses to maintain optimum performance under high-pressure conditions, which is a decisive factor for industries dependent on hydraulic systems’ efficacy. Experiential insights highlight that users consistently report a reduction in maintenance interventions after switching to China SAE100R14 hoses. The durable PTFE lining reduces wear and tear, elongating the service life of the hose and ensuring that maintenance resources are conserved, thereby offering a cost-effective solution without compromising on quality. Trust is a critical component when selecting hydraulic hoses, and China has cemented its position as a reputable producer through transparent manufacturing processes and open communication channels. With increasing globalization, quality assurance aligns with international certifications, providing end-users the confidence they require in their supply chain partnerships. Moreover, the competitive pricing models employed by Chinese manufacturers offer additional incentive without compromising the integrity or performance of the hoses. This cost-efficiency, coupled with reliable performance, provides industries the assurance needed to maintain continuity and confidence in their equipment and operational processes. In conclusion, China SAE100R14 hoses represent a harmonious blend of innovation, reliability, and cost-efficiency, backed by profound expertise, unwavering authoritativeness, and established trustworthiness. The strategic selection of these hoses offers an industry-leading solution that caters to the demanding requirements of diverse sectors, delivering unmatched performance that not only meets but also anticipates the evolving needs of modern applications.

The authoritativeness of Chinese-made SAE100R14 hoses is bolstered by the incorporation of fiber or steel wire braiding, which enhances the hose’s pressure capabilities without sacrificing flexibility. This structural integrity empowers the hoses to maintain optimum performance under high-pressure conditions, which is a decisive factor for industries dependent on hydraulic systems’ efficacy. Experiential insights highlight that users consistently report a reduction in maintenance interventions after switching to China SAE100R14 hoses. The durable PTFE lining reduces wear and tear, elongating the service life of the hose and ensuring that maintenance resources are conserved, thereby offering a cost-effective solution without compromising on quality. Trust is a critical component when selecting hydraulic hoses, and China has cemented its position as a reputable producer through transparent manufacturing processes and open communication channels. With increasing globalization, quality assurance aligns with international certifications, providing end-users the confidence they require in their supply chain partnerships. Moreover, the competitive pricing models employed by Chinese manufacturers offer additional incentive without compromising the integrity or performance of the hoses. This cost-efficiency, coupled with reliable performance, provides industries the assurance needed to maintain continuity and confidence in their equipment and operational processes. In conclusion, China SAE100R14 hoses represent a harmonious blend of innovation, reliability, and cost-efficiency, backed by profound expertise, unwavering authoritativeness, and established trustworthiness. The strategic selection of these hoses offers an industry-leading solution that caters to the demanding requirements of diverse sectors, delivering unmatched performance that not only meets but also anticipates the evolving needs of modern applications.

Share

Next:

Latest news

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025