12 月 . 04, 2024 09:23 Back to list

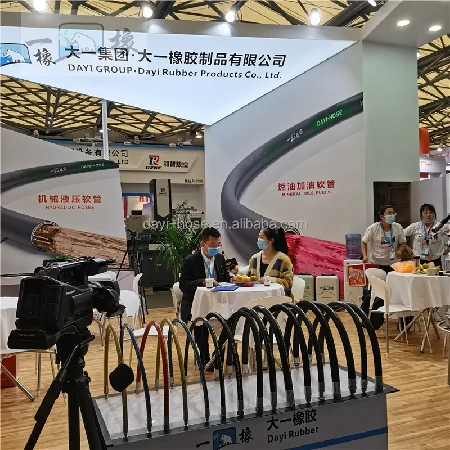

Leading Manufacturer of High-Pressure Hydraulic Rubber Hoses in China

China High Pressure Hydraulic Rubber Hose Manufacturers An Overview

In recent years, China has emerged as a global leader in the production and supply of high pressure hydraulic rubber hoses. These hoses play a crucial role in various industries, including construction, agriculture, mining, and manufacturing, where the efficient transfer of fluids under high pressure is essential. This article delves into the key features, manufacturing processes, and factors contributing to the prominence of Chinese manufacturers in this sector.

Understanding High Pressure Hydraulic Rubber Hoses

High pressure hydraulic rubber hoses are specifically designed to handle high pressures often exceeding 5000 psi. They are made from a blend of natural and synthetic rubber, reinforced with multiple layers of textile or steel wire to enhance strength and durability. The primary function of these hoses is to transmit hydraulic fluid to run machinery, tools, and equipment, making them an indispensable component in hydraulic systems.

Key Features

1. Durability and Flexibility High pressure hydraulic hoses manufactured in China exhibit exceptional durability and flexibility. The use of high-quality materials ensures resistance to abrasion, weather conditions, and extreme temperatures, making them suitable for various environments.

2. Standardization Chinese manufacturers adhere to international standards such as SAE (Society of Automotive Engineers) and ISO (International Organization for Standardization), ensuring that their products meet global quality benchmarks. This standardization is crucial for industries relying on stringent safety and operational guidelines.

3. Wide Range of Specifications Chinese manufacturers offer a diverse range of hydraulic hoses with different specifications to cater to various applications. These include variations in diameter, pressure ratings, and temperature tolerances, allowing customers to find the perfect hose for their specific needs.

4. Customization Many manufacturers in China provide customization options, enabling clients to tailor hoses according to their precise requirements. This service is particularly beneficial for companies needing specialized hoses for unique machinery or environmental conditions.

Manufacturing Processes

The manufacturing of high pressure hydraulic rubber hoses involves several steps

china high pressure hydraulic rubber hose manufacturer

1. Material Selection High-quality rubber compounds are selected based on the required specifications. These compounds are often mixed with additives to enhance properties like flexibility, heat resistance, and aging stability.

2. Reinforcement The hoses are reinforced using layers of synthetic fabrics or steel wire, which provides the necessary strength to withstand high pressures. The reinforcement process is critical, and it must be executed with precision to ensure the hose's structural integrity.

3. Extrusion and Vulcanization The hose is formed through an extrusion process, followed by vulcanization, a technique used to cure the rubber and enhance its durability. This process involves heating the hose under controlled conditions to create a strong and reliable product.

4. Testing and Quality Control Chinese manufacturers conduct rigorous testing at various stages of production to ensure that the hoses meet safety and performance standards. Tests may include pressure testing, temperature tolerance analysis, and inspection for defects.

Factors Contributing to Prominence

1. Cost-Effectiveness Chinese manufacturers are known for their competitive pricing. They benefit from an efficient supply chain and lower labor costs, allowing them to offer high-quality products at affordable rates.

2. Infrastructure Development The continuous improvement of infrastructure in China has facilitated the growth of manufacturing capabilities. Advanced machinery and technology have enhanced production speed and quality.

3. Export Market China is one of the largest exporters of hydraulic hoses worldwide. Manufacturers have established a robust export network, reaching markets in North America, Europe, and Asia, increasing their global footprint.

4. Continuous Innovation Chinese manufacturers invest in research and development to innovate and improve their product offerings. This focus on innovation helps them stay relevant in an ever-evolving market.

Conclusion

China’s high pressure hydraulic rubber hose manufacturers are setting benchmarks in quality, efficiency, and innovation. With their comprehensive understanding of industry needs, commitment to quality, and ability to offer competitive solutions, these manufacturers are not only meeting domestic demands but also successfully catering to international markets. As industries continue to advance and evolve, the role of these manufacturers will remain pivotal in supplying the essential hoses that power hydraulic systems across the globe.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025