8 月 . 17, 2024 23:53 Back to list

China High-Quality Single Fiber Braid Hydraulic Hose Manufacturing for Superior Performance and Durability

The Rise of Single Fiber Braid Hydraulic Hose Manufacturing in China

In recent years, China's manufacturing industry has gained significant recognition for its prowess in producing high-quality hydraulic components. Among these components, single fiber braid hydraulic hoses have emerged as a key product, showcasing China's commitment to innovation, quality, and efficiency in industrial applications.

Hydraulic hoses are crucial components in various industries, including construction, agriculture, and manufacturing. They transport hydraulic fluids, which are essential for operating machinery and equipment. The demand for reliable and durable hydraulic hoses has surged as industrial automation continues to expand, and among these, single fiber braid hydraulic hoses have become increasingly popular due to their superior characteristics.

The single fiber braid hydraulic hose is constructed using a single layer of synthetic fiber, typically polyester or nylon, which offers excellent flexibility, resistance to abrasion, and reduced weight compared to traditional steel wire braided hoses. This innovative design allows for greater maneuverability in tight spaces and makes handling easier for operators. Moreover, the composite materials used in these hoses contribute to their outstanding durability, making them suitable for high-pressure applications.

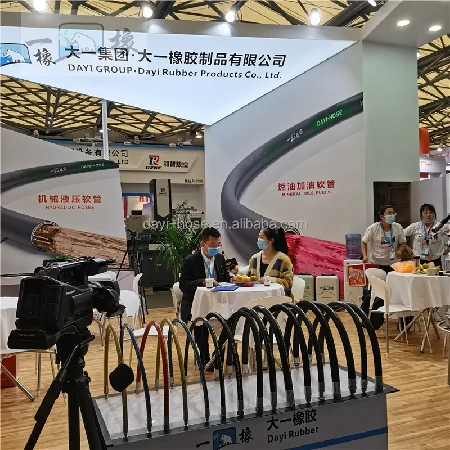

China's single fiber braid hydraulic hose factories are equipped with state-of-the-art technology and machinery, enabling them to produce hoses that meet international quality standards. Manufacturers have invested heavily in research and development to enhance the performance and longevity of their products. By employing advanced manufacturing techniques, such as precision weaving and advanced quality control systems, they can ensure that their hydraulic hoses exhibit consistent performance.

china single fiber braid hydraulic hose factory

One of the driving forces behind the success of single fiber braid hydraulic hoses in China is the combination of affordability and quality. Chinese manufacturers are able to offer competitive pricing, attracting a global client base while maintaining high manufacturing standards. This cost-effectiveness is largely due to the country's well-established supply chain and accessibility to raw materials. As a result, many international companies are turning to Chinese factories as reliable suppliers of hydraulic hoses.

Furthermore, the growing emphasis on sustainability in manufacturing has led to innovations in the production of hydraulic hoses. Many factories are adopting eco-friendly practices, such as reducing waste and utilizing recyclable materials, which appeal to environmentally conscious consumers. This shift not only aligns with global sustainability goals but also enhances the reputation of Chinese manufacturers in the eyes of international buyers.

The global hydraulic hose market is expected to witness significant growth in the coming years, driven by the expansion of the automotive and construction sectors. As industries increasingly focus on automation and efficiency, the demand for advanced hydraulic systems will continue to rise, further solidifying the role of single fiber braid hydraulic hoses. Chinese factories, known for their ability to scale production rapidly, are well-positioned to meet this rising demand while maintaining competitive delivery times.

In conclusion, China's single fiber braid hydraulic hose manufacturing sector exemplifies the country’s dedication to quality and innovation. With advanced technology, a skilled workforce, and a commitment to sustainability, Chinese manufacturers are at the forefront of producing high-performance hydraulic hoses. As the global market evolves, the role of these factories will undoubtedly expand, solidifying China's reputation as a leader in hydraulic component production. The future looks promising as these manufacturers continue to innovate and adapt to the changing needs of industries worldwide.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025