12 月 . 03, 2024 16:44 Back to list

air hose industrial

Understanding Air Hose Industrial Applications

In various industrial settings, the air hose serves as an essential component, facilitating the efficient transport of compressed air to power tools, machinery, and other equipment. As an integral part of pneumatic systems, air hoses are designed to withstand the demanding conditions of industrial environments. This article delves into the significance of air hoses in industry, their types, uses, and maintenance practices to ensure safety and efficiency.

The Importance of Air Hoses in Industry

Air hoses are crucial for various industries, including manufacturing, construction, automotive, and more. They provide a reliable means of delivering compressed air that drives pneumatic tools such as air drills, nail guns, sanders, and spray guns. The effective operation of these tools often depends on a stable and consistent air supply, which is where the quality of air hoses becomes paramount.

Moreover, air hoses contribute to the overall productivity of industrial operations. With the right air hose system in place, businesses can achieve faster turnaround times, reduce labor costs, and enhance overall efficiency. This advantage is particularly significant in high-paced environments, where delays in tool performance can lead to substantial losses.

Types of Air Hoses

There is a wide variety of air hoses available, each tailored to meet specific industrial needs. Understanding the different types can help businesses select the right hose for their applications

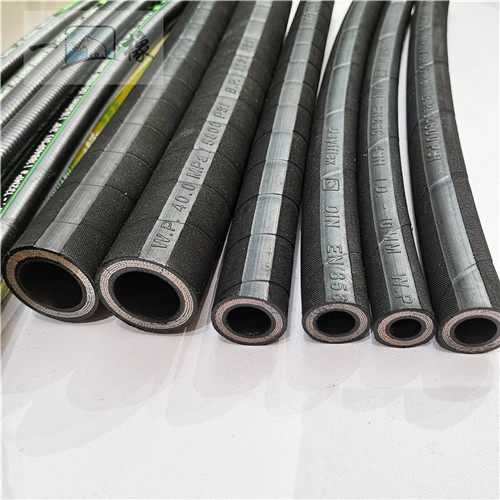

1. PVC Air Hoses Polyvinyl chloride (PVC) air hoses are lightweight, flexible, and resistant to abrasion and weathering. They are ideal for light-duty applications and are often used in general-purpose air supply tasks. 2. Rubber Air Hoses Known for their durability and ability to withstand extreme temperatures and harsh conditions, rubber air hoses are suitable for heavy-duty applications. They can handle higher pressure and are ideal for industries requiring frequent use of pneumatic tools.

3. Reinforced Air Hoses These hoses include additional layers of reinforcement, making them suitable for high-pressure applications. They are commonly used in industrial environments where durability and resistance to rupture are critical.

4. Coiled Air Hoses Designed to retain their shape and minimize tangling, coiled air hoses are convenient for dynamic environments where mobility is essential. They are often used in automotive repair shops and other applications where tools are frequently moved.

5. Silicone Air Hoses While not as common for compressed air, silicone hoses can be used in specific applications where flexibility and heat resistance are required, such as transferring air in high-temperature environments.

Key Considerations When Selecting Air Hoses

When choosing an air hose, several factors should be considered to ensure optimal performance and safety

air hose industrial

- Pressure Rating Always check the maximum pressure rating of the air hose to ensure it meets the requirements of the tools and machinery in use

.- Temperature Range Different hoses have varying temperature tolerances. Selecting a hose that can handle the specific temperature conditions of the work environment is vital for preventing hose failure.

- Length and Diameter The length and diameter of the hose affect air pressure and flow. Consider the layout of the workspace and how far the compressed air needs to travel.

- Compatibility Ensure that the air hose is compatible with the fittings and connectors being used in the pneumatic system to avoid leaks and inefficiency.

Maintenance Practices for Air Hoses

To prolong the life of air hoses and ensure safe operation, regular maintenance is essential. Here are some best practices

1. Inspect Regularly Check hoses for signs of wear, damage, or kinks. Replace any broken or worn hoses immediately to prevent accidents.

2. Store Properly Store hoses without sharp bends or twists, which could lead to premature wear. Using hose reels can also help keep them organized.

3. Check Connections Ensure that all connections are tight and free from leaks. Air leaks can significantly reduce efficiency and increase operational costs.

4. Clean Hoses Keep hoses clean and free from dust and debris, which can impede airflow and affect performance.

Conclusion

In summary, air hoses are vital components in industrial applications, providing a reliable means of delivering compressed air to various tools and machinery. Understanding the types of air hoses, their proper selection, and maintenance practices can enhance operational efficiency and safety in industrial settings. By investing time and resources into the right air hose solutions, businesses can improve productivity, reduce costs, and ensure a smooth workflow.

-

EN857 2SC Hydraulic Hose Suppliers OEM & China Manufacturers

NewsMay.30,2025

-

51mm Hydraulic Hose Manufacturer China OEM Durable & Custom Solutions

NewsMay.30,2025

-

OEM Rubber Air Hose Supplier Durable Custom Solutions

NewsMay.29,2025

-

High-Pressure Wrapped Cover Steel Wire Spiral Hydraulic Hose Supplier

NewsMay.29,2025

-

Rubber water suction and discharge hose

NewsMar.07,2025

-

SAE 100 R6/EN 854 R6 Fibre Braided Oil Hose

NewsMar.07,2025