Product Introduction

Braided smooth bore hose consists of a straight PTFE liner with a single or double stainless steel outer braid and is the basic PTFE hose design that has been successfully used in many automotive, fluid handling, chemical transfer, paint, pharmaceutical,Food and beverage processing, cosmetics and general applications.

The hose core is made of 100% virgin PTFE resin without any pigments or additives.

Wire braids are made of AISI 304 or 316 stainless steel wire.

- Crystallinity control of the PTFE inner tube (the crystallinity of the PTFE tube affects the pressure resistance and flexibility of the PTFE hose)

- Standard 304 stainless steel wire (better rust and corrosion resistance), no 201 stainless steel wire (201 stainless steel wire is cheaper than 304 stainless steel wire)

- Bold marks on the PTFE inner tube to ensure the PTFE hose cut does not open. Use hard 304 stainless steel wire (1600~2000MPAstrength). High quality PTFE hose machine for putting heavy marks on PTFE inner tubes.

|

Hose ID |

Hose OD |

Wall Thickness |

Working Pressure |

Burst Pressure |

Minimum Bend Radius |

|||

|

inch |

mm |

mm |

mm |

Mpa |

Psi |

Mpa |

Psi |

mm |

|

1/4 |

4.65-5.16 |

7.32-8.43 |

0.89 |

299 |

4330 |

897 |

13000 |

71 |

|

5/16 |

5.97-6.81 |

8.26-9.42 |

0.76 |

276 |

4000 |

828 |

12000 |

76 |

|

3/8 |

7.51-8.38 |

10.36-11.63 |

0.76 |

230 |

3330 |

690 |

10000 |

127 |

|

1/2 |

9.93-10.64 |

12.78-14.10 |

0.89 |

183 |

2660 |

552 |

8000 |

133 |

|

5/8 |

12.57-13.34 |

12.75-16.76 |

0.76 |

161 |

2330 |

483 |

7000 |

177 |

|

3/4 |

15.24-16.51 |

18.62-20.14 |

0.76 |

138 |

2000 |

414 |

6000 |

203 |

|

1 |

21.46-22.99 |

24.64-26.95 |

0.89 |

103 |

1500 |

310 |

4500 |

241 |

|

1-1/4 |

27.80-29.40 |

31.90-33.50 |

1.00 |

41 |

600 |

172 |

2500 |

406 |

Our advantage

High quality are our soul

All our products have a Two-Years!Two-Years!Two-Years warranty and will be returned and Pay Double!Pay Double!Pay Double if they have quality issue within two years

- 1.The inner rubber layer adopts the top raw material imported from Japan or South Korea: NBR, containing 35% rubber, hightemperature resistance, high pressure resistance and high strength.

- 2.Use the best domestic steel wire, German knitting machine, the best weaving technology 3*3, softer, smaller bending radius.

- 3.The outer rubber layer adopts CSM+CPE, which is more wear-resistant.

- 4.Automatic pressure testing equipment to ensure the quality of each hose.

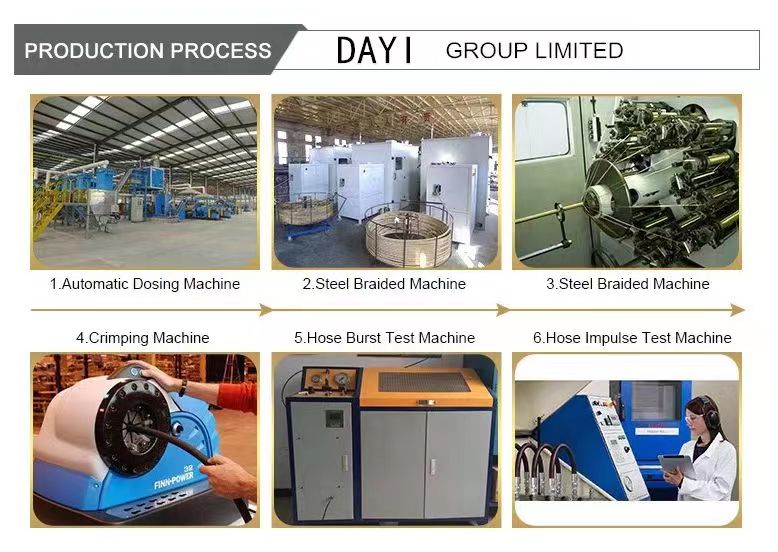

production process

pack

Application

The high pressure hose is mainly used for Mine hydraulic support ,oilfield exploitation ,object construction ,lifting transport metallurgic forging ,mine equipment, ship, injection molding machinery,agricultural machinery , all kinds of machine tools and various industrial sectors. Mechanization and automation in the hydraulic system of conveying with a certain pressure(high pressure) and the temperature of the oil-based(such as mineral oil, soluble oil, hydraulic oil, fuel oil and lubricants) and water-based liquid (such as Emulsion, the oil-water emulsion, water) and liquid transmission used.The maximum working pressure-resistant up to 70-100MPa.

Company

DAYI RUBBER PRODUCTS CO.LTD., established in 2012, is a professional manufacturer engaged in the research, development, production,sales and service of wrapped cover hydraulic hose, smooth cover hydraulic hose,gasoline hose, LPG&CNG hose and fiber braided hydraulic hose, We are located in Hengshui City, Hebei Province with convenient transportation access.

Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction at any time. In recent years, our company has introduced a series of advanced equipment, including high speed braiding machine, steel wire spiral machine, advanced extruding machine, computer-controlled water pressure test machine, impulse test bench. Moreover, we have newly built internal mixer workshop which can achieve raw material to rubber sheet by one time. In addition, we have obtained ISO9001 certificate, MSHA certificate and many patent certificates.

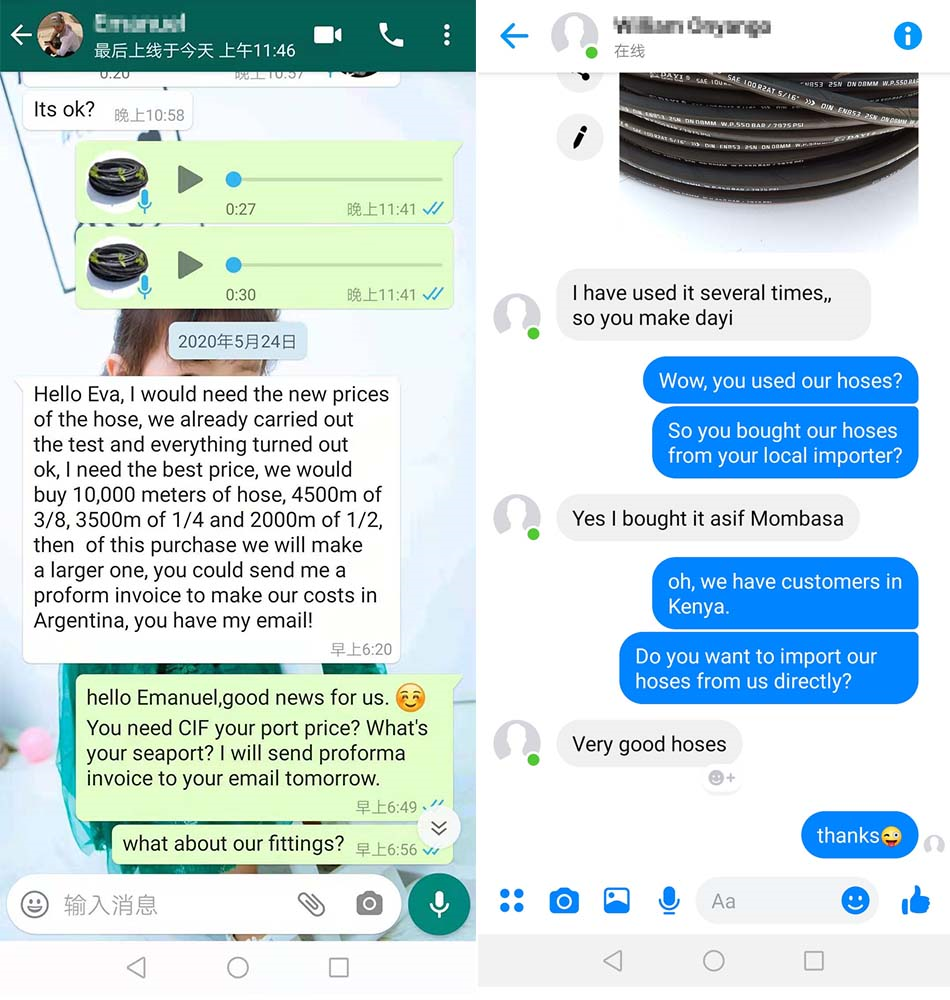

Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Germany, Italy, Spain, Turkey and South American countries. We also welcome OEM and ODM orders.We are looking forward to building win-win relationship with the customers worldwide. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements.

Teams

All of our sales staff have been professionally trained and are very professional in production process, process, sales and after-sales. All of them have more than 5 years of export experience. We will provide you with the best quality service

Certificate of DAYI

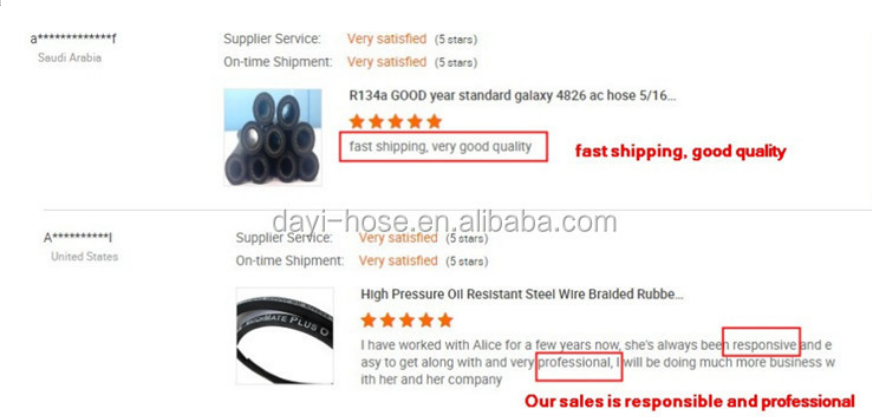

feedback information